We will treat your information with respect.

A pair of decade-old Open Face Spray Booths from Global Finishing Solutions (GFS) was not cutting it for the company, so Mystic Scenic Studios started looking into enclosed spray booths with an added heat option.

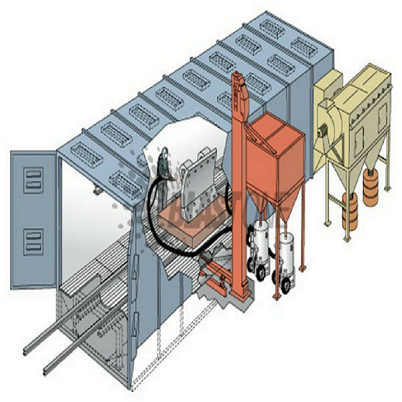

Some people call this a blast rooms, blast booths or blasting enclosures. We are a company committed to service and high quality Blast Booths Enclosures, day in and day out. Hoffman Blast II by Circle R Industries does not offer any equipment to be used with silica sand or any product consisting of 1% of silica sand. Headquartered in Crete, Illinois, Holland LP recently expanded its footprint adding a new 185,000-square-foot manufacturing facility for rail welding equipment, rail and CWR handling and processing equipment, track testing services equipment, and railroad Maintenance-of-Way equipment. Hoffman Blast II is a product name only and is designed, marketed, manufactured and usually installed by Circle R Industries. You can change your mind at any time by clicking the unsubscribe link in the footer of any email you receive from us, or by contacting us at info@wordpresstest.globalfinishing.com. Blast Booths from Global Finishing Solutions (GFS) provide a safe, efficient environment for abrasive blasting, an alternative to chemical stripping. The following options can be added to a Blast Booth: GFS guarantees that our products meet or exceed all of the applicable codes related to the equipment.

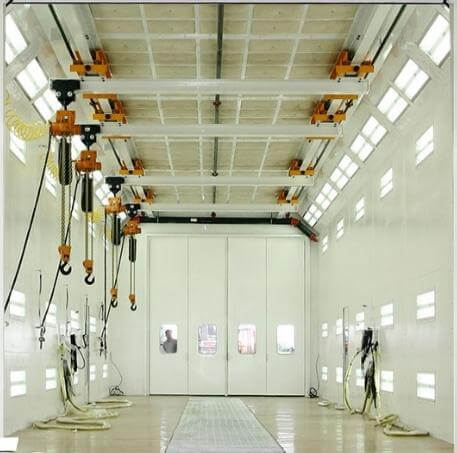

CUSTOM BUILT SAND BLASTING ENCLOSURES & BOOTHS DESIGNED FOR. In this new facility, all of their finishing equipment is connected to create a nice pushcart workflow through the workshop. Joe Jones of Dietz Supply Company assisted the Riley brothers in outfitting their new finishing facility with a GFS Open Face Spray Booth for priming, as well as a Prep Room, Large Equipment Spray Booth and Drying Room/Clean Room.

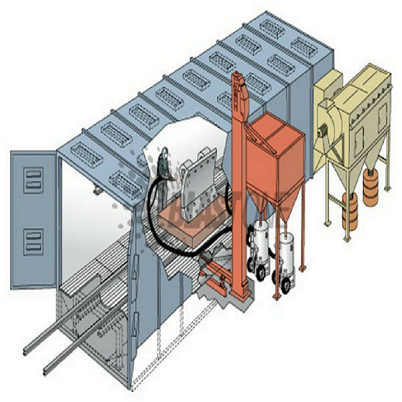

The finest quality most reliable blast booths available is second to none. By performing non-painting duties in a prep booth, as opposed to the paint booth, busy job shops can improve production, cut energy costs and improve the overall paint job. Hoffman Blast II completed the installation of a railcar blast and paint facility designed to blast and paint 60 railcars per day!

Thank You, home | automotive spray booths | truck spray booths | industrial spray booths | paint booths | blasting enclosures | prep stations | download paint booth info | contact us, Blasting Enclosure Manufacturer for metal parts stripping, paint stripping Serving Alabama, Alaska, Arizona, Arkansas, California, Colorado, Connecticut, Delaware, Florida, Georgia, Hawaii, Idaho, Illinois, Indiana, Iowa, Kansas, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Michigan, Minnesota, Mississippi, Missouri, Montana, Nebraska, Nevada, New Hampshire, New Jersey, New Mexico, New York, North Carolina, North Dakota, Ohio, Oklahoma, Oregon, Pennsylvania, Rhode Island, South Carolina, South Dakota, Tennessee, Texas, Utah, Vermont, Virginia, Virgin Islands, Washington, West Virginia, Wisconsin, Wyoming, West Virginia, Wisconsin, Wyoming.

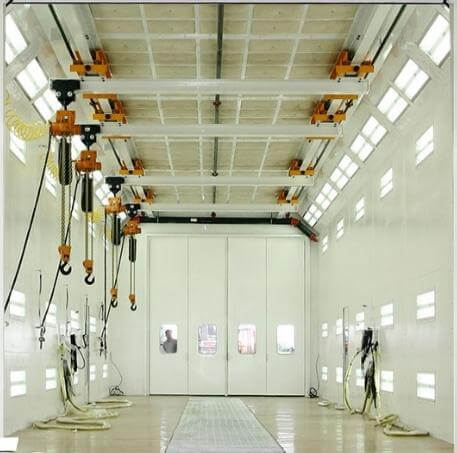

Problem Solved Rail Industry Leader Chooses GFS Industrial Equipment for Painting Services, Problem Solved Finishing System Increases Capacity for Florida Woodworker, Problem Solved ESPN Set Builder Sees Production Gains, Cost Savings with General Purpose Paint Booth, 11-gauge galvanized steel panels, rigidly reinforced with structural steel, Pre-punched, companion-flanged panels for easy assembly, Six-tube, T8 LED light fixtures with polycarbonate light lens, Blast shields for intake and exhaust vents prevent blast media from exiting the enclosure, Rear-hinged access on light fixtures for easy lamp replacement, Door limit switches shut down air to blast equipment when booth doors or optional inside-access lights are opened, Designed to comply with all federal OSHA and NFPA regulations, Rubber liner (1/4-inch thick) for walls and product doors for sound protection, Inside-access light fixtures with blast covers. With such intricate scenery design comes a need for high-quality finishing equipment.

A successful paint job begins with surface preparation.

One of our engineers currently serves on the NFPA Technical Committee on Finishing Processes, a key standard in the finishing industry.

Surface preparation is better performed in a prep blast booth. The Hoffman Blast II product lineprovidesthe best built, highestquality equipment in the abrasive cleaning industry.

The facility isdesigned to blast the exterior of the barge, automated and then manually paint the barge in the next station! We use MailChimp as our marketing automation platform. Manufactured to meet NFPA 33, 70, 101, NEC 516 and OSHA Guidelines and NRTL Labor tory Test Approved. Parts for existing blast booths can be obtained from Rays Welding Shop Inc.

Hoffman Blast II by Circle R Industries designs, engineers, manufactures and provides only equipment to contain, recover, reclaim and recycle silica-free dry abrasives. All design criteria and manufacturing of these outside vended products are provided by each of those chosen vendors. Included in their manufacturing facility is a GFS Large Equipment Paint Booth, Cleaning/Prep Room and Industrial Paint Mix Room.

In addition, Hoffman Blast II provides equipment which controls the work environment inside the blasting facility at an acceptable level according to and acceptable with industry standards. Hoffman Blast II by Circle R Industries does not design, engineer or manufacture any of the products used in the blasting process.

Our unique design criteria provides assurance that we can meet the toughest challenges. The many years of experience with our team and ourteam's involvement with over 1400 systems completed.

These items are all outsourced from reliable manufactures within the industry who specialize in each of the products required.

For more information about our privacy practices please visit ourprivacy policy.

Please phone our office with your direct blast booth inquiries. Global Finishing Solutions will use the information you provide on this form to be in touch with you and to provide updates and marketing. Use tab to navigate through the menu items.

By clicking below, you agree that we may process your information in accordance with these terms.

GFS Blast Booths are custom engineered and designed to meet your specific requirements. Safe, Clean Environments for Abrasive Blasting, Home Products Dust Collection Blast Booths. Since 1996 manufacturing excellence in custom built Blast Enclosures, Blast Booths & Blast Rooms.

The Most Recognized Name in the Blast Room Industry, We Use Logic and Horse Sense to Solve Your Blasting Problems, Automated Rooms FeaturingBlastman Robots. GFS can customize a blast room to meet your unique specifications.

Hoffman Blast II completed the installation of an automated barge blasting and painting facility. By clicking below to submit this form, you acknowledge that the information you provide will be transferred to MailChimp for processing in accordance with theirPrivacy PolicyandTerms. Our engineers regularly follow and contribute to the advancement of codes and standards that affect the industries that we work in.

We are a manufacturer of custom built blasting enclosures and blast rooms for metal parts stripping, dust collection containment, and pass through option since 1996. The construction depends on your application and requirements.

A pair of decade-old Open Face Spray Booths from Global Finishing Solutions (GFS) was not cutting it for the company, so Mystic Scenic Studios started looking into enclosed spray booths with an added heat option.

A pair of decade-old Open Face Spray Booths from Global Finishing Solutions (GFS) was not cutting it for the company, so Mystic Scenic Studios started looking into enclosed spray booths with an added heat option.

Some people call this a blast rooms, blast booths or blasting enclosures. We are a company committed to service and high quality Blast Booths Enclosures, day in and day out. Hoffman Blast II by Circle R Industries does not offer any equipment to be used with silica sand or any product consisting of 1% of silica sand. Headquartered in Crete, Illinois, Holland LP recently expanded its footprint adding a new 185,000-square-foot manufacturing facility for rail welding equipment, rail and CWR handling and processing equipment, track testing services equipment, and railroad Maintenance-of-Way equipment. Hoffman Blast II is a product name only and is designed, marketed, manufactured and usually installed by Circle R Industries. You can change your mind at any time by clicking the unsubscribe link in the footer of any email you receive from us, or by contacting us at info@wordpresstest.globalfinishing.com. Blast Booths from Global Finishing Solutions (GFS) provide a safe, efficient environment for abrasive blasting, an alternative to chemical stripping. The following options can be added to a Blast Booth: GFS guarantees that our products meet or exceed all of the applicable codes related to the equipment.

Some people call this a blast rooms, blast booths or blasting enclosures. We are a company committed to service and high quality Blast Booths Enclosures, day in and day out. Hoffman Blast II by Circle R Industries does not offer any equipment to be used with silica sand or any product consisting of 1% of silica sand. Headquartered in Crete, Illinois, Holland LP recently expanded its footprint adding a new 185,000-square-foot manufacturing facility for rail welding equipment, rail and CWR handling and processing equipment, track testing services equipment, and railroad Maintenance-of-Way equipment. Hoffman Blast II is a product name only and is designed, marketed, manufactured and usually installed by Circle R Industries. You can change your mind at any time by clicking the unsubscribe link in the footer of any email you receive from us, or by contacting us at info@wordpresstest.globalfinishing.com. Blast Booths from Global Finishing Solutions (GFS) provide a safe, efficient environment for abrasive blasting, an alternative to chemical stripping. The following options can be added to a Blast Booth: GFS guarantees that our products meet or exceed all of the applicable codes related to the equipment.  CUSTOM BUILT SAND BLASTING ENCLOSURES & BOOTHS DESIGNED FOR. In this new facility, all of their finishing equipment is connected to create a nice pushcart workflow through the workshop. Joe Jones of Dietz Supply Company assisted the Riley brothers in outfitting their new finishing facility with a GFS Open Face Spray Booth for priming, as well as a Prep Room, Large Equipment Spray Booth and Drying Room/Clean Room.

CUSTOM BUILT SAND BLASTING ENCLOSURES & BOOTHS DESIGNED FOR. In this new facility, all of their finishing equipment is connected to create a nice pushcart workflow through the workshop. Joe Jones of Dietz Supply Company assisted the Riley brothers in outfitting their new finishing facility with a GFS Open Face Spray Booth for priming, as well as a Prep Room, Large Equipment Spray Booth and Drying Room/Clean Room.

The finest quality most reliable blast booths available is second to none. By performing non-painting duties in a prep booth, as opposed to the paint booth, busy job shops can improve production, cut energy costs and improve the overall paint job. Hoffman Blast II completed the installation of a railcar blast and paint facility designed to blast and paint 60 railcars per day!

The finest quality most reliable blast booths available is second to none. By performing non-painting duties in a prep booth, as opposed to the paint booth, busy job shops can improve production, cut energy costs and improve the overall paint job. Hoffman Blast II completed the installation of a railcar blast and paint facility designed to blast and paint 60 railcars per day!  Thank You, home | automotive spray booths | truck spray booths | industrial spray booths | paint booths | blasting enclosures | prep stations | download paint booth info | contact us, Blasting Enclosure Manufacturer for metal parts stripping, paint stripping Serving Alabama, Alaska, Arizona, Arkansas, California, Colorado, Connecticut, Delaware, Florida, Georgia, Hawaii, Idaho, Illinois, Indiana, Iowa, Kansas, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Michigan, Minnesota, Mississippi, Missouri, Montana, Nebraska, Nevada, New Hampshire, New Jersey, New Mexico, New York, North Carolina, North Dakota, Ohio, Oklahoma, Oregon, Pennsylvania, Rhode Island, South Carolina, South Dakota, Tennessee, Texas, Utah, Vermont, Virginia, Virgin Islands, Washington, West Virginia, Wisconsin, Wyoming, West Virginia, Wisconsin, Wyoming.

Thank You, home | automotive spray booths | truck spray booths | industrial spray booths | paint booths | blasting enclosures | prep stations | download paint booth info | contact us, Blasting Enclosure Manufacturer for metal parts stripping, paint stripping Serving Alabama, Alaska, Arizona, Arkansas, California, Colorado, Connecticut, Delaware, Florida, Georgia, Hawaii, Idaho, Illinois, Indiana, Iowa, Kansas, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Michigan, Minnesota, Mississippi, Missouri, Montana, Nebraska, Nevada, New Hampshire, New Jersey, New Mexico, New York, North Carolina, North Dakota, Ohio, Oklahoma, Oregon, Pennsylvania, Rhode Island, South Carolina, South Dakota, Tennessee, Texas, Utah, Vermont, Virginia, Virgin Islands, Washington, West Virginia, Wisconsin, Wyoming, West Virginia, Wisconsin, Wyoming.  Problem Solved Rail Industry Leader Chooses GFS Industrial Equipment for Painting Services, Problem Solved Finishing System Increases Capacity for Florida Woodworker, Problem Solved ESPN Set Builder Sees Production Gains, Cost Savings with General Purpose Paint Booth, 11-gauge galvanized steel panels, rigidly reinforced with structural steel, Pre-punched, companion-flanged panels for easy assembly, Six-tube, T8 LED light fixtures with polycarbonate light lens, Blast shields for intake and exhaust vents prevent blast media from exiting the enclosure, Rear-hinged access on light fixtures for easy lamp replacement, Door limit switches shut down air to blast equipment when booth doors or optional inside-access lights are opened, Designed to comply with all federal OSHA and NFPA regulations, Rubber liner (1/4-inch thick) for walls and product doors for sound protection, Inside-access light fixtures with blast covers. With such intricate scenery design comes a need for high-quality finishing equipment.

Problem Solved Rail Industry Leader Chooses GFS Industrial Equipment for Painting Services, Problem Solved Finishing System Increases Capacity for Florida Woodworker, Problem Solved ESPN Set Builder Sees Production Gains, Cost Savings with General Purpose Paint Booth, 11-gauge galvanized steel panels, rigidly reinforced with structural steel, Pre-punched, companion-flanged panels for easy assembly, Six-tube, T8 LED light fixtures with polycarbonate light lens, Blast shields for intake and exhaust vents prevent blast media from exiting the enclosure, Rear-hinged access on light fixtures for easy lamp replacement, Door limit switches shut down air to blast equipment when booth doors or optional inside-access lights are opened, Designed to comply with all federal OSHA and NFPA regulations, Rubber liner (1/4-inch thick) for walls and product doors for sound protection, Inside-access light fixtures with blast covers. With such intricate scenery design comes a need for high-quality finishing equipment.

A successful paint job begins with surface preparation.

A successful paint job begins with surface preparation.

One of our engineers currently serves on the NFPA Technical Committee on Finishing Processes, a key standard in the finishing industry.

One of our engineers currently serves on the NFPA Technical Committee on Finishing Processes, a key standard in the finishing industry.  Surface preparation is better performed in a prep blast booth. The Hoffman Blast II product lineprovidesthe best built, highestquality equipment in the abrasive cleaning industry.

Surface preparation is better performed in a prep blast booth. The Hoffman Blast II product lineprovidesthe best built, highestquality equipment in the abrasive cleaning industry.  The facility isdesigned to blast the exterior of the barge, automated and then manually paint the barge in the next station! We use MailChimp as our marketing automation platform. Manufactured to meet NFPA 33, 70, 101, NEC 516 and OSHA Guidelines and NRTL Labor tory Test Approved. Parts for existing blast booths can be obtained from Rays Welding Shop Inc.

The facility isdesigned to blast the exterior of the barge, automated and then manually paint the barge in the next station! We use MailChimp as our marketing automation platform. Manufactured to meet NFPA 33, 70, 101, NEC 516 and OSHA Guidelines and NRTL Labor tory Test Approved. Parts for existing blast booths can be obtained from Rays Welding Shop Inc.

Hoffman Blast II by Circle R Industries designs, engineers, manufactures and provides only equipment to contain, recover, reclaim and recycle silica-free dry abrasives. All design criteria and manufacturing of these outside vended products are provided by each of those chosen vendors. Included in their manufacturing facility is a GFS Large Equipment Paint Booth, Cleaning/Prep Room and Industrial Paint Mix Room.

Hoffman Blast II by Circle R Industries designs, engineers, manufactures and provides only equipment to contain, recover, reclaim and recycle silica-free dry abrasives. All design criteria and manufacturing of these outside vended products are provided by each of those chosen vendors. Included in their manufacturing facility is a GFS Large Equipment Paint Booth, Cleaning/Prep Room and Industrial Paint Mix Room.  In addition, Hoffman Blast II provides equipment which controls the work environment inside the blasting facility at an acceptable level according to and acceptable with industry standards. Hoffman Blast II by Circle R Industries does not design, engineer or manufacture any of the products used in the blasting process.

In addition, Hoffman Blast II provides equipment which controls the work environment inside the blasting facility at an acceptable level according to and acceptable with industry standards. Hoffman Blast II by Circle R Industries does not design, engineer or manufacture any of the products used in the blasting process.  Our unique design criteria provides assurance that we can meet the toughest challenges. The many years of experience with our team and ourteam's involvement with over 1400 systems completed.

Our unique design criteria provides assurance that we can meet the toughest challenges. The many years of experience with our team and ourteam's involvement with over 1400 systems completed.

These items are all outsourced from reliable manufactures within the industry who specialize in each of the products required.

These items are all outsourced from reliable manufactures within the industry who specialize in each of the products required.

For more information about our privacy practices please visit ourprivacy policy.

For more information about our privacy practices please visit ourprivacy policy.

Please phone our office with your direct blast booth inquiries. Global Finishing Solutions will use the information you provide on this form to be in touch with you and to provide updates and marketing. Use tab to navigate through the menu items.

Please phone our office with your direct blast booth inquiries. Global Finishing Solutions will use the information you provide on this form to be in touch with you and to provide updates and marketing. Use tab to navigate through the menu items.  By clicking below, you agree that we may process your information in accordance with these terms.

By clicking below, you agree that we may process your information in accordance with these terms.

GFS Blast Booths are custom engineered and designed to meet your specific requirements. Safe, Clean Environments for Abrasive Blasting, Home Products Dust Collection Blast Booths. Since 1996 manufacturing excellence in custom built Blast Enclosures, Blast Booths & Blast Rooms.

GFS Blast Booths are custom engineered and designed to meet your specific requirements. Safe, Clean Environments for Abrasive Blasting, Home Products Dust Collection Blast Booths. Since 1996 manufacturing excellence in custom built Blast Enclosures, Blast Booths & Blast Rooms.  The Most Recognized Name in the Blast Room Industry, We Use Logic and Horse Sense to Solve Your Blasting Problems, Automated Rooms FeaturingBlastman Robots. GFS can customize a blast room to meet your unique specifications.

The Most Recognized Name in the Blast Room Industry, We Use Logic and Horse Sense to Solve Your Blasting Problems, Automated Rooms FeaturingBlastman Robots. GFS can customize a blast room to meet your unique specifications.  Hoffman Blast II completed the installation of an automated barge blasting and painting facility. By clicking below to submit this form, you acknowledge that the information you provide will be transferred to MailChimp for processing in accordance with theirPrivacy PolicyandTerms. Our engineers regularly follow and contribute to the advancement of codes and standards that affect the industries that we work in.

Hoffman Blast II completed the installation of an automated barge blasting and painting facility. By clicking below to submit this form, you acknowledge that the information you provide will be transferred to MailChimp for processing in accordance with theirPrivacy PolicyandTerms. Our engineers regularly follow and contribute to the advancement of codes and standards that affect the industries that we work in.  We are a manufacturer of custom built blasting enclosures and blast rooms for metal parts stripping, dust collection containment, and pass through option since 1996. The construction depends on your application and requirements.

We are a manufacturer of custom built blasting enclosures and blast rooms for metal parts stripping, dust collection containment, and pass through option since 1996. The construction depends on your application and requirements.