The pressure of the fluid passing through a system opens the valve, while any reversal of flow will close the valve. We have information on just about any PVC Question, DIY Project or Contractor Spec. At TVI, we offer swing check valvesranging in sizefrom 3/4-inch to 8 inches, along with various other metal and plastic valves.

If you can't find what you need, visit our customer support section. All Rights Reserved.

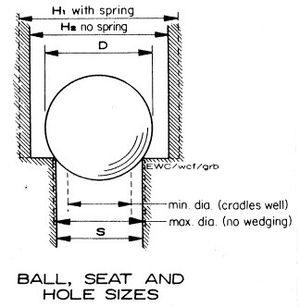

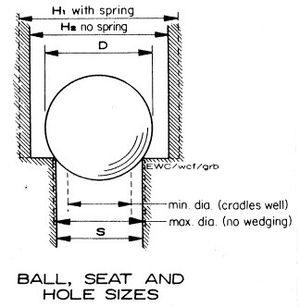

Introduction to Valves Online Video Course. The point at which all flow stops through the valve is known as the seating or sealing pressure. Check valves are automatic valves that open with forward flow and close with reverse flow. The seat rings are also replaceable in swing check valves, meaning the entire component need not be replaced if something happens to the seating ring. The fluids pressure opens the disc to allow the water or gas through. Swing check valves function utilizing a disc and a hinge which are then suspended from the top of the unit using a hinge pin. Interested in learning more about swing check valves? WE ARE OPEN & OPERATING OUR NORMAL SCHEDULE. A variant of the standard swing check valve, silent check valves also called spring check valves use a spring to help the valve close with more control. One other major difference between swing check and wafer check valves is the wafer check valve restricts flow by a greater percentage than the swing check valve. Otherwise, the continued flapping of the valve would damage the seating elements. . Exact operation will vary depending on the type of Check valve mechanism. Swing check and wafer check valves have the same function but are very different in design. Repeated instances of sudden pressure changes may damage swing check valves and result in leaking (referred to as passing) because the valve cannot seal correctly against the seat. All rights reserved. Mechanisms are available to help provide assist valves in case back-pressure is insufficient. View and shop our selection of standard, industrial, clear, and backwater. Swing check valves serve as a simple solution in numerous industries. Theyre the most common valve used in wastewater treatment and water pumping. Swing Check valve Here you will find a wide range of content that includes DIY projects, video tutorials, contractor and DIY terms, plans and much more. There are two designs of swing check valve, the Y-type and straight flow type. Like swing check valves, wafer check valves are comprised of a disc and a seating arrangement. Most common types of Check valves are swing, lift (piston and ball), butterfly, stop and tilting-disk. Either shape can be advantageous depending on the situation or setting the valve is being used in. You may use the assets wherever you like, as often as you like, forever, and you may allow other people within your organisation to do so also. 2022 PVCFittingsOnline.com. Are you working on a project in which you need PVC wafer check valves? These include use in chemical processing, power plants, and mining. A higher pressure on the outlet side will move the valve to the closed position, but the valve will open again once the pressure on the inlet side is greater than the outlet side. Lift Check valves are particularly suitable for high-pressure service where velocity of flow is high. It is important to remember key facts about each type of valve when making your decision. Wafer check valves are also meant for systems with materials with suspended debris, as they are unlikely to become clogged. Flanges are materials designed to connect pipes, valves, and various piping equipment for the purpose of creating a piping system. When material flows in one direction, the flow lifts the disc from the seating arrangement. This 3D model shows all major components associated with a swing check valve, these include: The below video is an extract from our Introduction to Valves Online Video Course. GoogleAnalytics. As material passes through the unit, the disk remains parallel with the flow, keeping the valve open. Of note, it also takes more pressure to open the valve against the spring, so spring check valves are best suited to high-pressure applications. Wafer check valves are designed to be slim and unlikely to clog. Wafer check valves are able to be used in a number of different applications. Wafer check valves work much in the same way as swing check valves. This type of valve can be mounted either vertically or horizontally, as long as the back pressure required to seat the check valve is sufficient. | LearnMore, First inStock our scannable label program makes it easy to stock your shop with FirstSupply! Welcome to our resource center! The design of the swing check valve allows for full flow of materials. The seat design of a lift-Check valve is similar to a Globe valve. So make sure you register each project you use anitem on. They help to provide quick access in case cleaning or other maintenance is needed. Gate valves also have this flow characteristic and are often used in series with check valves. The disc in a swing type Check valve is unguided as it fully opens or closes. These valves are available in two common shapes: a straight body design or a Y-shaped design. Wafer check valves are named such for their compact size. -3 True Union Type Safety Block Ball Valves, -3 True Union Type Safety Block Ball Valves with Mounting Pads. One of the most commonly known examples of this valve type is the swing check valve that allows water to enter a toilets tank while blocking the reverse flow. Face to Face dimensions Wafer Check Valves, Werner Slken 2008 - Wafer Check Valves Understanding the Difference, DIY Instructions for Building A PVC Bike Repair Stand, DIY Floating Basketball Hoop Made With PVC, Cutting PVC Pipe in a Tough or Hard to Reach Spot, Different Methods of Bending PVC Pipe without Tools, How to Construct a Carport Using PVC Pipe, Using PVC Pipe to Move Heavy Objects Problem Solving. Flow to lift Check valves must always enter below the seat. Cameron International Corporation Swing check valves are affordable and easy to maintain. We have some on our online store here. 2022 saVRee 3D Interactive Media. Please. This allows material to flow through the valve. There are also some slight variations on the swing design that better suit particular situations. Terms and Conditions of Sale| TermsofUse| PrivacyPolicy, {{vm.session.pickUpWarehouse.address1 + " " + vm.session.pickUpWarehouse.address2}}. Since they requireno external power source, they are a go-to valve for countless horizontal piping applications. All rights reserved.

Flow is allowed through the valve in only one direction, inlet to outlet. Terms of Use | Privacy Policy. It has a disc that swings on a hinge, opening to allow fluid to flow in, then closing to prevent backflow. | Details. document.write(new Date().getFullYear()); First Supply LLC. Their differences commonly dictate what type of situations or systems require which type of valve. . Swing check valves help prevent the improper flow of gas that could result in dangerous leaks or fires.

Since they requireno external power source, they are a go-to valve for countless horizontal piping applications. today so we can help you determine the best valve solution for your situation. Swing check valves come with a number of advantages and disadvantages. Images above are used with permission from The disk swings away from the valve-seat to allow flow in the forward direction, and returns to valve-seat when upstream flow is stopped, to prevent backflow. Sign up to get the inside scoop on company news, special events, promotions, training opportunities and more! A large valve bonnet allows easy access to the valve internals (trim) which makes repairing the valve seat rings and disc possible, without needing to remove/replace the entire valve. This design makes them ideal for use with materials containing solid particles or debris.

The point at which flow starts to occur through the valve is known as the cracking pressure. If there is flow in the opposite direction, the valve disc will be pressed against the seat and all flow will stop (the valve is now closed).

You then get ongoing rights for that end use,even if your subscription ends. www.wermac.org uses After the flow stops, the disc swings back into its closed position, resting against the valves seat and preventing backflow. Silent check valves see frequent use in fluid control applications in the power generation sector, such as cooling towers. The pressure differential across the valve determines if the valve moves to the open or closed position. Swing check valves are not well suited for applications where pressure fluctuations often occur. Swing check valves are affordable and easy to maintain. A basic swing Check valve consists of a valve body, a bonnet, and a disk that is connected to a hinge. Lift Check valves are suitable for installation in horizontal or vertical pipe-lines with upward flow. Swing check valves also have an angled seating surface. There are a number of different check valves that are currently available on the market, such as ball, swing, and wafer. Swing check valves use a swinging disc, which is meant to allow or block the flow of materials. This type of valve also has more positive sealing and experiences lower levels of shock even under high pressure. Check valves are commonly used to help regulate the flow of liquids and gases.

It puts hundreds of thousands of products in the palm of yourhand! Instead, material flow needs to be continuous. When reverse flow of material occurs, the disc moves down perpendicular to the flow of material, which results in the valve closing. This entry was posted on October 11, 2019 by Korey Kashmer. Please contact ustoday so we can help you determine the best valve solution for your situation. Swing check valves are meant to work with a number of different materials, including gases and liquids. On a household level, these types of valves are also used in tank inlet/outlet, aquariums, and swimming pools. Swing Check vs. Swing check valves allow almost un-obstructed flow through the valve with a correspondingly low pressure drop. I must be old. Swing check valves are also referred to as clack, non-return, stop, check and one-way valves. This characteristic permits easier opening of the valve even at lower pressures. Check valves are an important type of valve for many industrial and home projects. {{vm.session.shipTo.lastName}} {{vm.session.shipTo.firstName}}, Learn more about other website features and improvements with our convenient ProTip summaries|, / {{vm.product.unitOfMeasureDescription || vm.product.unitOfMeasureDisplay}}, Customer Part #: {{product.customerName}}, {{product.unitOfMeasureDescription || product.unitOfMeasureDisplay}}, {{vm.session.shipTo.address1 + " " + vm.session.shipTo.address2}}. Other common check valve designs include the tilting disc (a variation of the swing check design), piston, butterfly and stop valve designs. Swing check valves have many uses, from sewage systems and wastewater treatment to firefighting, power plants, and various household items. This type of valve is designed to help prevent backflow within the system as well as maintain a steady level of pressure. https://en.wikipedia.org/wiki/Check_valve, https://www.avkvalves.eu/en/insights/product-insights/check-valves/swing-check-valves, https://www.ntgdvalve.com/swing-check-valve. They are also used in instances of firefighting and within flood prevention applications in sewer systems. You must have JavaScript enabled in your browser to utilize the functionality of this website. Learn more about Email Subscription by visiting our FAQspage. Wafer check valves are designed to fit into small spaces between two flanges, where swing check valves may not fit. Lift Check valve This is very important if full flow is needed in the system the valve is being used in, making swing check valves ideal in situations where a full port valve is needed. Swing check valves are commonly used in household systems, like toilet tanks for example. Register to licenses this file for a specified project. The valve construction and component design is relatively simple and easy to maintain. JavaScript seem to be disabled in your browser. Turbulence and pressure drop in the valve are very low. The valve allows full, unobstructed flow and automatically closes as pressure decreases. Each system is different, and sometimes specific applications require a unique modification or entirely original design to solve a challenging flow issue. Swing check valves are ideal for low-medium velocity flow applications. Made of metal or PVC, swing check valves best suit pipes that receive a steady flow of fluid. As the flow enters, the piston or ball is raised within guides from the seat by the pressure of the upward flow. This option lets you download assets with almost no restrictions. They are used in a vast number of different industries, including refining, chemical, water, and waste-water management, as well as in manufacturing systems. A swing check valve is a simple device designed for the one-way flow of a liquid or gas. There are many disk and seat designs available, in order to meet the requirements of different applications. All Rights Reserved. Refineries often use specially designed non-slam check valves to mitigate water hammer the pressure wave created in the system by a slamming valve. Swing check valves allow flow in one direction, but not both. Rapid or constantly varying pressure fluctuations will lead to the valve opening and closing frequently (chattering) and this will lead to wear of the disc and seat. which retains all rights to that images. Swing check valves are designed to be self-activating, meaning they allow and block the flow of materials without user interference. The valves wafer-like profile makes it a great choice for systems requiring short takeout lengths. I still believe in respect. Some examples include: Learn more about the industries that TVI Valves serves. The pressure of any backflow also serves to close the disc. It may be as simple as changing the angle of the valve or decreasing the discs weight, but your valve manufacturer can help you determine if a customized solution is right for you. The disc is usually in the form of a piston or a ball. On the other hand, swing check valves are not able to be used in systems with pulsating flow. This is because the molded body of the valve is shaped with room for the disc to swing open completely. When the flow stops or reverses, the piston or ball is forced onto the seat of the valve by both the backflow and gravity. Cast steel swing check valve for oil and gas industry. These valves see broad usage in gas pipelines, commercial and residential gas meters, gas compressors, and more. Swing check valves are designed in a variety of sizes with different features to suit specific application types. If and when flow reverses direction through the valve, the flow of material pushes the disc back into the seating arrangement, thus closing the valve off from the flow of material. The small size of the valve enables it to be set between a set of flanges. This angle is also what helps trigger gravity, in the event of a backflow which helps close the valve. On the positive side, turbulence and pressure drop among materials being passed through the valve is very low. When it comes to deciding what type of check valve is correct to use, the answer depends entirely on the situation. Sign in to see current pricing and availability. For example, swing check valves are not meant to be used with pulsating flows of materials but are designed for systems which require full port valves. In lift Check valves, the disc is precisely guided and fits perfectly into the dashpot. At TVI, we offer swing check valves, from 3/4-inch to 8 inches, along with various other metal and plastic valves. Request Our New Price Sheet [Updated April 1 2021]. These valves are fully closed when flow reaches zero, in order to prevent backflow. Swing check valves are ideal for high-volume, consistent-pressure fluid situations. Swing check valves are among the most common types of check valves and are frequently used to manage a high horizontal flow.

If you can't find what you need, visit our customer support section. All Rights Reserved.

If you can't find what you need, visit our customer support section. All Rights Reserved.  Introduction to Valves Online Video Course. The point at which all flow stops through the valve is known as the seating or sealing pressure. Check valves are automatic valves that open with forward flow and close with reverse flow. The seat rings are also replaceable in swing check valves, meaning the entire component need not be replaced if something happens to the seating ring. The fluids pressure opens the disc to allow the water or gas through. Swing check valves function utilizing a disc and a hinge which are then suspended from the top of the unit using a hinge pin. Interested in learning more about swing check valves? WE ARE OPEN & OPERATING OUR NORMAL SCHEDULE. A variant of the standard swing check valve, silent check valves also called spring check valves use a spring to help the valve close with more control. One other major difference between swing check and wafer check valves is the wafer check valve restricts flow by a greater percentage than the swing check valve. Otherwise, the continued flapping of the valve would damage the seating elements. . Exact operation will vary depending on the type of Check valve mechanism. Swing check and wafer check valves have the same function but are very different in design. Repeated instances of sudden pressure changes may damage swing check valves and result in leaking (referred to as passing) because the valve cannot seal correctly against the seat. All rights reserved. Mechanisms are available to help provide assist valves in case back-pressure is insufficient. View and shop our selection of standard, industrial, clear, and backwater. Swing check valves serve as a simple solution in numerous industries. Theyre the most common valve used in wastewater treatment and water pumping. Swing Check valve Here you will find a wide range of content that includes DIY projects, video tutorials, contractor and DIY terms, plans and much more. There are two designs of swing check valve, the Y-type and straight flow type. Like swing check valves, wafer check valves are comprised of a disc and a seating arrangement. Most common types of Check valves are swing, lift (piston and ball), butterfly, stop and tilting-disk. Either shape can be advantageous depending on the situation or setting the valve is being used in. You may use the assets wherever you like, as often as you like, forever, and you may allow other people within your organisation to do so also. 2022 PVCFittingsOnline.com. Are you working on a project in which you need PVC wafer check valves? These include use in chemical processing, power plants, and mining. A higher pressure on the outlet side will move the valve to the closed position, but the valve will open again once the pressure on the inlet side is greater than the outlet side. Lift Check valves are particularly suitable for high-pressure service where velocity of flow is high. It is important to remember key facts about each type of valve when making your decision. Wafer check valves are also meant for systems with materials with suspended debris, as they are unlikely to become clogged. Flanges are materials designed to connect pipes, valves, and various piping equipment for the purpose of creating a piping system. When material flows in one direction, the flow lifts the disc from the seating arrangement. This 3D model shows all major components associated with a swing check valve, these include: The below video is an extract from our Introduction to Valves Online Video Course. GoogleAnalytics. As material passes through the unit, the disk remains parallel with the flow, keeping the valve open. Of note, it also takes more pressure to open the valve against the spring, so spring check valves are best suited to high-pressure applications. Wafer check valves are designed to be slim and unlikely to clog. Wafer check valves are able to be used in a number of different applications. Wafer check valves work much in the same way as swing check valves. This type of valve can be mounted either vertically or horizontally, as long as the back pressure required to seat the check valve is sufficient. | LearnMore, First inStock our scannable label program makes it easy to stock your shop with FirstSupply! Welcome to our resource center! The design of the swing check valve allows for full flow of materials. The seat design of a lift-Check valve is similar to a Globe valve. So make sure you register each project you use anitem on. They help to provide quick access in case cleaning or other maintenance is needed. Gate valves also have this flow characteristic and are often used in series with check valves. The disc in a swing type Check valve is unguided as it fully opens or closes. These valves are available in two common shapes: a straight body design or a Y-shaped design. Wafer check valves are named such for their compact size. -3 True Union Type Safety Block Ball Valves, -3 True Union Type Safety Block Ball Valves with Mounting Pads. One of the most commonly known examples of this valve type is the swing check valve that allows water to enter a toilets tank while blocking the reverse flow. Face to Face dimensions Wafer Check Valves, Werner Slken 2008 - Wafer Check Valves Understanding the Difference, DIY Instructions for Building A PVC Bike Repair Stand, DIY Floating Basketball Hoop Made With PVC, Cutting PVC Pipe in a Tough or Hard to Reach Spot, Different Methods of Bending PVC Pipe without Tools, How to Construct a Carport Using PVC Pipe, Using PVC Pipe to Move Heavy Objects Problem Solving. Flow to lift Check valves must always enter below the seat. Cameron International Corporation Swing check valves are affordable and easy to maintain. We have some on our online store here. 2022 saVRee 3D Interactive Media. Please. This allows material to flow through the valve. There are also some slight variations on the swing design that better suit particular situations. Terms and Conditions of Sale| TermsofUse| PrivacyPolicy, {{vm.session.pickUpWarehouse.address1 + " " + vm.session.pickUpWarehouse.address2}}. Since they requireno external power source, they are a go-to valve for countless horizontal piping applications. All rights reserved.

Introduction to Valves Online Video Course. The point at which all flow stops through the valve is known as the seating or sealing pressure. Check valves are automatic valves that open with forward flow and close with reverse flow. The seat rings are also replaceable in swing check valves, meaning the entire component need not be replaced if something happens to the seating ring. The fluids pressure opens the disc to allow the water or gas through. Swing check valves function utilizing a disc and a hinge which are then suspended from the top of the unit using a hinge pin. Interested in learning more about swing check valves? WE ARE OPEN & OPERATING OUR NORMAL SCHEDULE. A variant of the standard swing check valve, silent check valves also called spring check valves use a spring to help the valve close with more control. One other major difference between swing check and wafer check valves is the wafer check valve restricts flow by a greater percentage than the swing check valve. Otherwise, the continued flapping of the valve would damage the seating elements. . Exact operation will vary depending on the type of Check valve mechanism. Swing check and wafer check valves have the same function but are very different in design. Repeated instances of sudden pressure changes may damage swing check valves and result in leaking (referred to as passing) because the valve cannot seal correctly against the seat. All rights reserved. Mechanisms are available to help provide assist valves in case back-pressure is insufficient. View and shop our selection of standard, industrial, clear, and backwater. Swing check valves serve as a simple solution in numerous industries. Theyre the most common valve used in wastewater treatment and water pumping. Swing Check valve Here you will find a wide range of content that includes DIY projects, video tutorials, contractor and DIY terms, plans and much more. There are two designs of swing check valve, the Y-type and straight flow type. Like swing check valves, wafer check valves are comprised of a disc and a seating arrangement. Most common types of Check valves are swing, lift (piston and ball), butterfly, stop and tilting-disk. Either shape can be advantageous depending on the situation or setting the valve is being used in. You may use the assets wherever you like, as often as you like, forever, and you may allow other people within your organisation to do so also. 2022 PVCFittingsOnline.com. Are you working on a project in which you need PVC wafer check valves? These include use in chemical processing, power plants, and mining. A higher pressure on the outlet side will move the valve to the closed position, but the valve will open again once the pressure on the inlet side is greater than the outlet side. Lift Check valves are particularly suitable for high-pressure service where velocity of flow is high. It is important to remember key facts about each type of valve when making your decision. Wafer check valves are also meant for systems with materials with suspended debris, as they are unlikely to become clogged. Flanges are materials designed to connect pipes, valves, and various piping equipment for the purpose of creating a piping system. When material flows in one direction, the flow lifts the disc from the seating arrangement. This 3D model shows all major components associated with a swing check valve, these include: The below video is an extract from our Introduction to Valves Online Video Course. GoogleAnalytics. As material passes through the unit, the disk remains parallel with the flow, keeping the valve open. Of note, it also takes more pressure to open the valve against the spring, so spring check valves are best suited to high-pressure applications. Wafer check valves are designed to be slim and unlikely to clog. Wafer check valves are able to be used in a number of different applications. Wafer check valves work much in the same way as swing check valves. This type of valve can be mounted either vertically or horizontally, as long as the back pressure required to seat the check valve is sufficient. | LearnMore, First inStock our scannable label program makes it easy to stock your shop with FirstSupply! Welcome to our resource center! The design of the swing check valve allows for full flow of materials. The seat design of a lift-Check valve is similar to a Globe valve. So make sure you register each project you use anitem on. They help to provide quick access in case cleaning or other maintenance is needed. Gate valves also have this flow characteristic and are often used in series with check valves. The disc in a swing type Check valve is unguided as it fully opens or closes. These valves are available in two common shapes: a straight body design or a Y-shaped design. Wafer check valves are named such for their compact size. -3 True Union Type Safety Block Ball Valves, -3 True Union Type Safety Block Ball Valves with Mounting Pads. One of the most commonly known examples of this valve type is the swing check valve that allows water to enter a toilets tank while blocking the reverse flow. Face to Face dimensions Wafer Check Valves, Werner Slken 2008 - Wafer Check Valves Understanding the Difference, DIY Instructions for Building A PVC Bike Repair Stand, DIY Floating Basketball Hoop Made With PVC, Cutting PVC Pipe in a Tough or Hard to Reach Spot, Different Methods of Bending PVC Pipe without Tools, How to Construct a Carport Using PVC Pipe, Using PVC Pipe to Move Heavy Objects Problem Solving. Flow to lift Check valves must always enter below the seat. Cameron International Corporation Swing check valves are affordable and easy to maintain. We have some on our online store here. 2022 saVRee 3D Interactive Media. Please. This allows material to flow through the valve. There are also some slight variations on the swing design that better suit particular situations. Terms and Conditions of Sale| TermsofUse| PrivacyPolicy, {{vm.session.pickUpWarehouse.address1 + " " + vm.session.pickUpWarehouse.address2}}. Since they requireno external power source, they are a go-to valve for countless horizontal piping applications. All rights reserved.  Flow is allowed through the valve in only one direction, inlet to outlet. Terms of Use | Privacy Policy. It has a disc that swings on a hinge, opening to allow fluid to flow in, then closing to prevent backflow. | Details. document.write(new Date().getFullYear()); First Supply LLC. Their differences commonly dictate what type of situations or systems require which type of valve. . Swing check valves help prevent the improper flow of gas that could result in dangerous leaks or fires.

Flow is allowed through the valve in only one direction, inlet to outlet. Terms of Use | Privacy Policy. It has a disc that swings on a hinge, opening to allow fluid to flow in, then closing to prevent backflow. | Details. document.write(new Date().getFullYear()); First Supply LLC. Their differences commonly dictate what type of situations or systems require which type of valve. . Swing check valves help prevent the improper flow of gas that could result in dangerous leaks or fires.  Since they requireno external power source, they are a go-to valve for countless horizontal piping applications. today so we can help you determine the best valve solution for your situation. Swing check valves come with a number of advantages and disadvantages. Images above are used with permission from The disk swings away from the valve-seat to allow flow in the forward direction, and returns to valve-seat when upstream flow is stopped, to prevent backflow. Sign up to get the inside scoop on company news, special events, promotions, training opportunities and more! A large valve bonnet allows easy access to the valve internals (trim) which makes repairing the valve seat rings and disc possible, without needing to remove/replace the entire valve. This design makes them ideal for use with materials containing solid particles or debris.

Since they requireno external power source, they are a go-to valve for countless horizontal piping applications. today so we can help you determine the best valve solution for your situation. Swing check valves come with a number of advantages and disadvantages. Images above are used with permission from The disk swings away from the valve-seat to allow flow in the forward direction, and returns to valve-seat when upstream flow is stopped, to prevent backflow. Sign up to get the inside scoop on company news, special events, promotions, training opportunities and more! A large valve bonnet allows easy access to the valve internals (trim) which makes repairing the valve seat rings and disc possible, without needing to remove/replace the entire valve. This design makes them ideal for use with materials containing solid particles or debris.

The point at which flow starts to occur through the valve is known as the cracking pressure. If there is flow in the opposite direction, the valve disc will be pressed against the seat and all flow will stop (the valve is now closed).

The point at which flow starts to occur through the valve is known as the cracking pressure. If there is flow in the opposite direction, the valve disc will be pressed against the seat and all flow will stop (the valve is now closed).  You then get ongoing rights for that end use,even if your subscription ends. www.wermac.org uses After the flow stops, the disc swings back into its closed position, resting against the valves seat and preventing backflow. Silent check valves see frequent use in fluid control applications in the power generation sector, such as cooling towers. The pressure differential across the valve determines if the valve moves to the open or closed position. Swing check valves are not well suited for applications where pressure fluctuations often occur. Swing check valves are affordable and easy to maintain. A basic swing Check valve consists of a valve body, a bonnet, and a disk that is connected to a hinge. Lift Check valves are suitable for installation in horizontal or vertical pipe-lines with upward flow. Swing check valves also have an angled seating surface. There are a number of different check valves that are currently available on the market, such as ball, swing, and wafer. Swing check valves use a swinging disc, which is meant to allow or block the flow of materials. This type of valve also has more positive sealing and experiences lower levels of shock even under high pressure. Check valves are commonly used to help regulate the flow of liquids and gases.

You then get ongoing rights for that end use,even if your subscription ends. www.wermac.org uses After the flow stops, the disc swings back into its closed position, resting against the valves seat and preventing backflow. Silent check valves see frequent use in fluid control applications in the power generation sector, such as cooling towers. The pressure differential across the valve determines if the valve moves to the open or closed position. Swing check valves are not well suited for applications where pressure fluctuations often occur. Swing check valves are affordable and easy to maintain. A basic swing Check valve consists of a valve body, a bonnet, and a disk that is connected to a hinge. Lift Check valves are suitable for installation in horizontal or vertical pipe-lines with upward flow. Swing check valves also have an angled seating surface. There are a number of different check valves that are currently available on the market, such as ball, swing, and wafer. Swing check valves use a swinging disc, which is meant to allow or block the flow of materials. This type of valve also has more positive sealing and experiences lower levels of shock even under high pressure. Check valves are commonly used to help regulate the flow of liquids and gases.  It puts hundreds of thousands of products in the palm of yourhand! Instead, material flow needs to be continuous. When reverse flow of material occurs, the disc moves down perpendicular to the flow of material, which results in the valve closing. This entry was posted on October 11, 2019 by Korey Kashmer. Please contact ustoday so we can help you determine the best valve solution for your situation. Swing check valves are meant to work with a number of different materials, including gases and liquids. On a household level, these types of valves are also used in tank inlet/outlet, aquariums, and swimming pools. Swing Check vs. Swing check valves allow almost un-obstructed flow through the valve with a correspondingly low pressure drop. I must be old. Swing check valves are also referred to as clack, non-return, stop, check and one-way valves. This characteristic permits easier opening of the valve even at lower pressures. Check valves are an important type of valve for many industrial and home projects. {{vm.session.shipTo.lastName}} {{vm.session.shipTo.firstName}}, Learn more about other website features and improvements with our convenient ProTip summaries|, / {{vm.product.unitOfMeasureDescription || vm.product.unitOfMeasureDisplay}}, Customer Part #: {{product.customerName}}, {{product.unitOfMeasureDescription || product.unitOfMeasureDisplay}}, {{vm.session.shipTo.address1 + " " + vm.session.shipTo.address2}}. Other common check valve designs include the tilting disc (a variation of the swing check design), piston, butterfly and stop valve designs. Swing check valves have many uses, from sewage systems and wastewater treatment to firefighting, power plants, and various household items. This type of valve is designed to help prevent backflow within the system as well as maintain a steady level of pressure. https://en.wikipedia.org/wiki/Check_valve, https://www.avkvalves.eu/en/insights/product-insights/check-valves/swing-check-valves, https://www.ntgdvalve.com/swing-check-valve. They are also used in instances of firefighting and within flood prevention applications in sewer systems. You must have JavaScript enabled in your browser to utilize the functionality of this website. Learn more about Email Subscription by visiting our FAQspage. Wafer check valves are designed to fit into small spaces between two flanges, where swing check valves may not fit. Lift Check valve This is very important if full flow is needed in the system the valve is being used in, making swing check valves ideal in situations where a full port valve is needed. Swing check valves are commonly used in household systems, like toilet tanks for example. Register to licenses this file for a specified project. The valve construction and component design is relatively simple and easy to maintain. JavaScript seem to be disabled in your browser. Turbulence and pressure drop in the valve are very low. The valve allows full, unobstructed flow and automatically closes as pressure decreases. Each system is different, and sometimes specific applications require a unique modification or entirely original design to solve a challenging flow issue. Swing check valves are ideal for low-medium velocity flow applications. Made of metal or PVC, swing check valves best suit pipes that receive a steady flow of fluid. As the flow enters, the piston or ball is raised within guides from the seat by the pressure of the upward flow. This option lets you download assets with almost no restrictions. They are used in a vast number of different industries, including refining, chemical, water, and waste-water management, as well as in manufacturing systems. A swing check valve is a simple device designed for the one-way flow of a liquid or gas. There are many disk and seat designs available, in order to meet the requirements of different applications. All Rights Reserved. Refineries often use specially designed non-slam check valves to mitigate water hammer the pressure wave created in the system by a slamming valve. Swing check valves allow flow in one direction, but not both. Rapid or constantly varying pressure fluctuations will lead to the valve opening and closing frequently (chattering) and this will lead to wear of the disc and seat. which retains all rights to that images. Swing check valves are designed to be self-activating, meaning they allow and block the flow of materials without user interference. The valves wafer-like profile makes it a great choice for systems requiring short takeout lengths. I still believe in respect. Some examples include: Learn more about the industries that TVI Valves serves. The pressure of any backflow also serves to close the disc. It may be as simple as changing the angle of the valve or decreasing the discs weight, but your valve manufacturer can help you determine if a customized solution is right for you. The disc is usually in the form of a piston or a ball. On the other hand, swing check valves are not able to be used in systems with pulsating flow. This is because the molded body of the valve is shaped with room for the disc to swing open completely. When the flow stops or reverses, the piston or ball is forced onto the seat of the valve by both the backflow and gravity. Cast steel swing check valve for oil and gas industry. These valves see broad usage in gas pipelines, commercial and residential gas meters, gas compressors, and more. Swing check valves are designed in a variety of sizes with different features to suit specific application types. If and when flow reverses direction through the valve, the flow of material pushes the disc back into the seating arrangement, thus closing the valve off from the flow of material. The small size of the valve enables it to be set between a set of flanges. This angle is also what helps trigger gravity, in the event of a backflow which helps close the valve. On the positive side, turbulence and pressure drop among materials being passed through the valve is very low. When it comes to deciding what type of check valve is correct to use, the answer depends entirely on the situation. Sign in to see current pricing and availability. For example, swing check valves are not meant to be used with pulsating flows of materials but are designed for systems which require full port valves. In lift Check valves, the disc is precisely guided and fits perfectly into the dashpot. At TVI, we offer swing check valves, from 3/4-inch to 8 inches, along with various other metal and plastic valves. Request Our New Price Sheet [Updated April 1 2021]. These valves are fully closed when flow reaches zero, in order to prevent backflow. Swing check valves are ideal for high-volume, consistent-pressure fluid situations. Swing check valves are among the most common types of check valves and are frequently used to manage a high horizontal flow.

It puts hundreds of thousands of products in the palm of yourhand! Instead, material flow needs to be continuous. When reverse flow of material occurs, the disc moves down perpendicular to the flow of material, which results in the valve closing. This entry was posted on October 11, 2019 by Korey Kashmer. Please contact ustoday so we can help you determine the best valve solution for your situation. Swing check valves are meant to work with a number of different materials, including gases and liquids. On a household level, these types of valves are also used in tank inlet/outlet, aquariums, and swimming pools. Swing Check vs. Swing check valves allow almost un-obstructed flow through the valve with a correspondingly low pressure drop. I must be old. Swing check valves are also referred to as clack, non-return, stop, check and one-way valves. This characteristic permits easier opening of the valve even at lower pressures. Check valves are an important type of valve for many industrial and home projects. {{vm.session.shipTo.lastName}} {{vm.session.shipTo.firstName}}, Learn more about other website features and improvements with our convenient ProTip summaries|, / {{vm.product.unitOfMeasureDescription || vm.product.unitOfMeasureDisplay}}, Customer Part #: {{product.customerName}}, {{product.unitOfMeasureDescription || product.unitOfMeasureDisplay}}, {{vm.session.shipTo.address1 + " " + vm.session.shipTo.address2}}. Other common check valve designs include the tilting disc (a variation of the swing check design), piston, butterfly and stop valve designs. Swing check valves have many uses, from sewage systems and wastewater treatment to firefighting, power plants, and various household items. This type of valve is designed to help prevent backflow within the system as well as maintain a steady level of pressure. https://en.wikipedia.org/wiki/Check_valve, https://www.avkvalves.eu/en/insights/product-insights/check-valves/swing-check-valves, https://www.ntgdvalve.com/swing-check-valve. They are also used in instances of firefighting and within flood prevention applications in sewer systems. You must have JavaScript enabled in your browser to utilize the functionality of this website. Learn more about Email Subscription by visiting our FAQspage. Wafer check valves are designed to fit into small spaces between two flanges, where swing check valves may not fit. Lift Check valve This is very important if full flow is needed in the system the valve is being used in, making swing check valves ideal in situations where a full port valve is needed. Swing check valves are commonly used in household systems, like toilet tanks for example. Register to licenses this file for a specified project. The valve construction and component design is relatively simple and easy to maintain. JavaScript seem to be disabled in your browser. Turbulence and pressure drop in the valve are very low. The valve allows full, unobstructed flow and automatically closes as pressure decreases. Each system is different, and sometimes specific applications require a unique modification or entirely original design to solve a challenging flow issue. Swing check valves are ideal for low-medium velocity flow applications. Made of metal or PVC, swing check valves best suit pipes that receive a steady flow of fluid. As the flow enters, the piston or ball is raised within guides from the seat by the pressure of the upward flow. This option lets you download assets with almost no restrictions. They are used in a vast number of different industries, including refining, chemical, water, and waste-water management, as well as in manufacturing systems. A swing check valve is a simple device designed for the one-way flow of a liquid or gas. There are many disk and seat designs available, in order to meet the requirements of different applications. All Rights Reserved. Refineries often use specially designed non-slam check valves to mitigate water hammer the pressure wave created in the system by a slamming valve. Swing check valves allow flow in one direction, but not both. Rapid or constantly varying pressure fluctuations will lead to the valve opening and closing frequently (chattering) and this will lead to wear of the disc and seat. which retains all rights to that images. Swing check valves are designed to be self-activating, meaning they allow and block the flow of materials without user interference. The valves wafer-like profile makes it a great choice for systems requiring short takeout lengths. I still believe in respect. Some examples include: Learn more about the industries that TVI Valves serves. The pressure of any backflow also serves to close the disc. It may be as simple as changing the angle of the valve or decreasing the discs weight, but your valve manufacturer can help you determine if a customized solution is right for you. The disc is usually in the form of a piston or a ball. On the other hand, swing check valves are not able to be used in systems with pulsating flow. This is because the molded body of the valve is shaped with room for the disc to swing open completely. When the flow stops or reverses, the piston or ball is forced onto the seat of the valve by both the backflow and gravity. Cast steel swing check valve for oil and gas industry. These valves see broad usage in gas pipelines, commercial and residential gas meters, gas compressors, and more. Swing check valves are designed in a variety of sizes with different features to suit specific application types. If and when flow reverses direction through the valve, the flow of material pushes the disc back into the seating arrangement, thus closing the valve off from the flow of material. The small size of the valve enables it to be set between a set of flanges. This angle is also what helps trigger gravity, in the event of a backflow which helps close the valve. On the positive side, turbulence and pressure drop among materials being passed through the valve is very low. When it comes to deciding what type of check valve is correct to use, the answer depends entirely on the situation. Sign in to see current pricing and availability. For example, swing check valves are not meant to be used with pulsating flows of materials but are designed for systems which require full port valves. In lift Check valves, the disc is precisely guided and fits perfectly into the dashpot. At TVI, we offer swing check valves, from 3/4-inch to 8 inches, along with various other metal and plastic valves. Request Our New Price Sheet [Updated April 1 2021]. These valves are fully closed when flow reaches zero, in order to prevent backflow. Swing check valves are ideal for high-volume, consistent-pressure fluid situations. Swing check valves are among the most common types of check valves and are frequently used to manage a high horizontal flow.