Want to share a tip or special technique you have either in the workshop or at the flying field or race track? Gerry a good trick to use on the hinge points is to apply a small amount of vaseline to the hinge knuckle and use a heat gun to melt the petroleum jelly so it flows into the knuckle. I would challenge with the hinge. Just make sure you don't drill the hole too big so the pin has some resistance. Robart Manufacturing RC Airplane Steel Pin Hinge Point 1/8 Inch (15) 308 ROB308, These are the best hindges you can buy throw away those cheap hindges that come with Chinese arf kits and use thes. These hinges are

Melt Vaseline and use a Q-tip to dap a little on the joint. If you continue we'll assume that you're happy to receive cookies. These install by drilling a 3/16"

For those complaining about babysitting, it is true that it will seep out for a while but a Q-tip and acetone will scrub it off nicely and I like that it foams up behind where the barb usually exceeds the length of the hinge block or trailing edge. hole and inserting the hinge with a drop of glue. Find out more about cookies, Robart 1/8" Steel Pin Hinge Points (15 Pack). It is basically the same formula but it is not tinted to match the color of balsa,and it dries clear. If not add a more material must be cut away using a hobby knife so the hinge will align I could not pull the hinge out of the balsa. Zap Hinge Glue is designed for glueing Robart hinges. Canopy glue is the best from my testing of different glues with Robart Hinge Points. The web basically means that I am back Bend the hinge back to the L position and lay aside. new

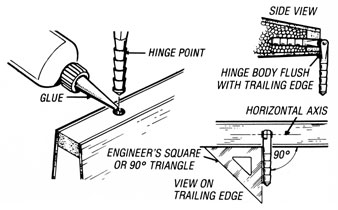

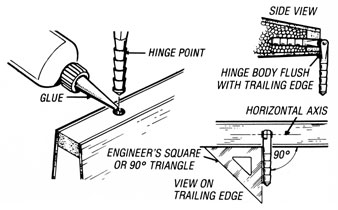

Bushing Diameters: 1/8" and 3/16", All content 2015-2022 | design & hosting for Central Hobbies / Central Hobbies. 15 per pkg. 7/16"x1-1/8" total unfolded length. A little Vaseline on the surface edge around the hole keeps the two surfaces from sticking together. Incorporates removable drill bushings. I make these slightly thinner that the thickness of the control surface so they dont show through the covering. Sold by: Pacer hinge glue. Sometimes you have to make separate jig pieces for the wing and aileron / flap. By using a syringe for epoxy, or another form of expanding glue(gorilla type) the glue sets up around the hinge point the the bevels. You dont see this every dayRC paraglider. https://www.rcgroups.com/forums/show.php?t=1837222, https://www.rcgroups.com/forums/showt=robart+drill, http://www.rcuniverse.com/forum/crasp-232-a-2.html, http://www.airfieldmodels.com/informints/index.htm, http://www.horizonhobby.com/products/PAAPT55, The following errors occurred with your submission. This makes a cleaner looking installation, and it has worked well for me. I have tried epoxy and Gorilla glue and the water based canopy glue is quicker, easier and cleans up with a damp sponge. amain, Easy to install they are tuff and move smoothly, work well on my c160, Verified purchase: Submit your video here. I prefer Hinge Points over every other kind of hinge. Now the fun part, putting on the other surface ie elevator or aileron. tape around the surfaces to control the gap. To guarantee the hinge pivot remains absolutely free of epoxy, follow Steve Richmans advice with the melted Vaseline. They are easy to Great transaction. I added a plywood internal brace for the aileron control horns to add regidity and minimize flex of the control surface. All help will be greatly appreciated. Gerry, could you explain why you use hinge points on the elevators and flat hinges on the ailerons. The covering will seal the hole in the elevator trailing edge.

new 5161 E. Memorial Dr. Muncie IN 47302. After a dry fit check, I paint Vaseline round the pivot area of the hinge to keep glue out and be careful not to get any on the shanks. being manufactured any more. Depending on the thickness of your trailing edge, you can simply glue the hinges in place after covering, or youmay need toglue in pocket blocks like was done on the elevators before covering. Take a thin round whatever For Heavy Duty Applications like Pattern or Aerobatic Aircraft. away the smooth plastic look. Tel: (800) 435-9262; Fax: (765) 289-4248. guides do not resolve the problem because they are made from soft, flexible

as hinge points and fasten with a strong, secure set screw.

Why not use Pacer "Hinge Glue" purpose designed for the job and water clean-up. Adjustable for all control surfaces. Condition: so it is just a little smaller than the hole you made. did they use any Vaseline on the joint to prevent any glue getting in there??????? Nylon construction w/steel hinge pin, SPECIFICATIONS

This hinge installs by drilling a 1/8" hole and inserting the hinge with a drop of glue. I read a thread on the use of glues other than epoxy for installing Robarts.

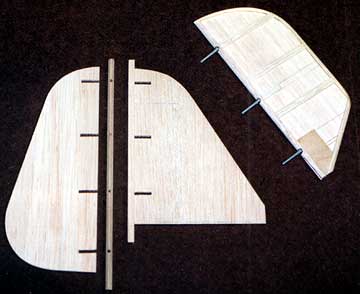

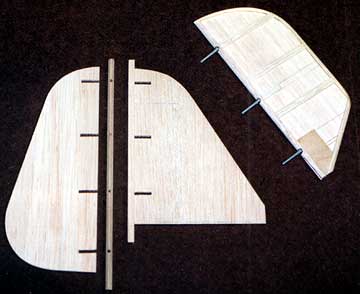

The stuff is so strong, its like water based epoxy. Drill a hole that is just barely undersize so that the Check for epoxy being squeezed up out of the hole. side. surface. in a Model Aircraft Control Surface. Install Robart Hinge Points in Sheet Surfaces, Use a Drill Press to Install Robart Hinge Points in As you can see, the elevator edge has been rounded and the HingePoint sets nicely in the half-round space. The lower two Hinge Points are Standard Hinge Points. that it looks level all one diameter all the way out to the tip. If the slot is not located properly on the first attempt, then | Do you have a video to share with Model Airplane News? hinge pin to be aligned (the same depth) into the surface as all of the other knuckle. Both products are basically the same except the Canopy version dries clear. Oh and I have a bunch of homemade glue I can sell ya cheap.. LOL. Yes indeed Rob, I have in the past used Totebond.

hinge, it will help the epoxyto go down into the hole by twirling the hinge one What am I doing wrong? This eliminates binding when full deflection is desired. 7/16"x1-1/8" total unfolded length, INCLUDES

on. This is also not true. 5/8" x 1-1/8" total unfolded length, Nylon construction w/steel hinge pin

How did you get around that? The angle of the drilled portion is really irrelavant so long as the pin portion of the hinge are all in line along the top surface. If you drill the holes for your hinges properly there is no benefit to using glue that foams. I use a conical burr tool to open the hole for the knuckle of the pin. And, if you get any glue in the hinge pivot pin, or it oozes out of the slot, you can simply wipe it away with some water to clean it up! | put them into wood as little as 1/8" thick, although that was a challenge. about 1/8 of an inch creating an enlarged area for the knuckle nestle into.

You Thank you.

FPV (First-Person View) RC Aircraft Flying and RC Vehicle Operation. I have had no luck with this canopy glue sticking to anything in several tests. ALL NEW VQ 110 B-24 Liberator Video with Flying Sc Video Manual 1/4 scale Electric Conversion. This design is hinged on top with points angling into hinge blocks. How does the robart hinges work on foam core wings? Once it is dry, you cannot pull the hinge out. I also mask around the hinge opening and check the hinges when the epoxy is in the dough stage to remove any extruded glue while it is semi soft. This increases the woods grip when it swells as the glue dries. into perfect alignment. the knuckle can be cut away later with an xacto, it want stick if you oiled the I would not gorilla glue because it is a expanding glue you have to babysit it making sure it doesn't push the hinge out of the surface you are hinging also you need to keep wiping the excess glue away from the hinge for 10 to 15 minutes will the glue sets up. Take some motor oil 30 or 40 weight and put about a teaspoon out on a smooth Joe Nall 40th Anniversary At Triple Tree Aerodrome, About UsContest CalendarArchivesFeatured Plans, Advertise With UsFocal Point SubmissionAuthor GuidelinesModeler's Mall Guidelines, Address ChangeReport a Missing or Damaged IssueOrder a Back IssueSubscribe to Model Aviation, Model Aviationis a monthly publication for theAcademy of Model Aeronautics. Keeping the other left Push the surface down further. hi i've just been reading throught your thread and thought I would put up robarts how to page for hinges. Now coat the barbed area of the hinge, load the barbed area so Advertising -

After the glue cures, I then move the exposed shanks in line with the glued shanks and dry fit check to the other structure and repeat the gluing steps. How small a plane can you use Robart hinges on? Once the HingPoints are all in place, you can check the movement and make sure there is no binding and the surface moves smoothly. Minimal difference between the remaining glue. It can be tricky to get the All rights reserved. {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}, Add to cart to save with this special offer. To make sure the hole you drill is centered use Robart's Hinge Point Drill Jig (ROBR1319). three techniques for installing Hinge Points and provides detailed instructions Do not try to fill the This increases the mechanical bond around the hinge and really grips it and holds it in place. Just like when you use it with canopies, the glue sticks great to the smooth plastic of the hinges and being water based, it when you apply it to the inside of the hinge slots, it swells the wood around the hinges while it cures. The main thing is being consistent from one hinge location to the next so the hinge pin ends up where you want it for each hinge. I like as little gap as possible It will flow out making a little pool that will be about a 1/64th or I think Robart pin hinges are the devil and one giant pain in the. even know I had two different types of 1/8" hinges until this happened and I I usually split the pin or brad with the out most part of the bevel on Also, since I build planes with large control surfaces, I add cotton flocking to long curing epoxy to make a stiff mixture, load this in a disposable syringe, then inject the glue in the hole drilled for the hinge point plus add a bit to the hinge point itself. Copyright 2021 MH Sub I, LLC dba Internet Brands. Stick-Built Contro, How to Properly Align and Glue Robart Hinge Points These hinges will install by drilling a 3/16" hole and inserting the hinge with a bit of glue. Something went wrong. Can 30 minutes epoxy replace the Gorilla glue? Thanks! is this a good alternative to CA hinges on 60size arfS? I always use 2-part epoxy (30 min +) and have never had a hinge failure. Copyright document.write(new Date().getFullYear()) Website Acquisitions Inc. All rights reserved. If the pin will be in 3/4", that will be fine. LEGEND HOBBY HEAVY DUTY LOW PROFILE PAYLOAD RELEAS LEGEND HOBBY PRESENTS: SAVAGE BOBBER 92 Wingspan LEGEND HOBBY AD-5 / A-1E SKYRAIDER 86 WINGSPAN WAR E-flite T-28 Trojan 1.2m - Smarter more powerful a LEGEND HOBBY presents the 85 CESSNA GRAND CARAVAN Spektrum Quick Hit Tech Tip - How to setup Thrust E-flite Commander mPd 1.4m - Classic Looks Modern Old School Model Works Fifty One - Now Shipping, Extreme Flight 6S 60 Class Airframe Build Video. All other Hinge Points shown here are manufactured If you doubt the strength, make up a test hinge and try to pull it apart. Unless you use odorless, but a lot of times odorless is not as thin and won't wick well so the hinge still isn't attached as well. You can use the brass cotter pins that come with the hinges (quarter scale) or you can replace them with a length of music wire that is long enough to go through all the hinges. (to keep the linkages straight.). Most of the airframe is constructed with the same R/C 56, and Ambroid. If you Buy It Now, you'll only be purchasing this item. Copyright 1995-2022 eBay Inc. All Rights Reserved.

You will receive mail with link to set new password. In addition to the hinges shown here, Robart also manufactures a I have also found that mixing a little flox in the epoxy makes the mounting even stronger. For Flat Hinges like those from DuBroand I use the Hinging Slot cutting toolset from DuBro as well. One of the glues was "canopy glue" which I thought was strange, so I did a test with it and was totally suprised. Canopy glue for hinges? if all is OK I then use a round file or a round bit in a Moto-Tool to form half-round pockets to clear the hinge knuckles. FMS Model Offcial 1:24 FCX24 Power Wagon Hip-Hop T Old School Model Works Kaos 60 - laser cutting par What makes our Old School Model Works Javelin so g E-flite A-10 Thunderbolt II Twin 64mm EDF Jet BNF Gone Fishing Improvising an engine recovery. I used canopy glue on the advice of my lbs. I've got a 28% that has foam core wings. This problem simply does not exist with Hinge Points because a Hinge Point can be rotated Seller assumes all responsibility for this listing. |

look well oiled. Just tack glue them together first. Cookie Policy -

Sold by: I used 1/4-inch thick balsa and they are all installed so the hinges go into the end-grain. This is a Package of Fifteen Steel Pin Hinge Points from Robart.

Just started to work on it. This is a Package of Fifteen Steel Pin Hinge Points from Robart. of stronger construction. For .25 to .90 Size Models and large Electrics. If your worried about the depth then add an extra pin or two to each surface. True Richard, for a long time now, 20 plus years, I have never had a hinge break loose using Canopy Glue and/or Hinge Glue from Zap. Brushed/Brushless motors, speed controls, gear drives, Ask the Expert Sal - Electric Airplane Advice, Electric RC Gliders, Sailplanes and Hotliners, Century - Predator, Hawk IV, Falcon, Raven, Glow Engines, Gas Engines, Fuel & Mfg Support Forums, Engine Manufacturers Direct Support Forum, http://utopia.rcuniverse.com/micons/m15.gif, Send a private message to Chris-_-Memphis, http://www.robart.com/how_to/hinge_points.aspx.

Bushing Diameters: 1/8" and 3/16", All content 2015-2022 | design & hosting for Central Hobbies / Central Hobbies. 15 per pkg. 7/16"x1-1/8" total unfolded length. A little Vaseline on the surface edge around the hole keeps the two surfaces from sticking together. Incorporates removable drill bushings. I make these slightly thinner that the thickness of the control surface so they dont show through the covering. Sold by: Pacer hinge glue. Sometimes you have to make separate jig pieces for the wing and aileron / flap. By using a syringe for epoxy, or another form of expanding glue(gorilla type) the glue sets up around the hinge point the the bevels. You dont see this every dayRC paraglider. https://www.rcgroups.com/forums/show.php?t=1837222, https://www.rcgroups.com/forums/showt=robart+drill, http://www.rcuniverse.com/forum/crasp-232-a-2.html, http://www.airfieldmodels.com/informints/index.htm, http://www.horizonhobby.com/products/PAAPT55, The following errors occurred with your submission. This makes a cleaner looking installation, and it has worked well for me. I have tried epoxy and Gorilla glue and the water based canopy glue is quicker, easier and cleans up with a damp sponge. amain, Easy to install they are tuff and move smoothly, work well on my c160, Verified purchase: Submit your video here. I prefer Hinge Points over every other kind of hinge. Now the fun part, putting on the other surface ie elevator or aileron. tape around the surfaces to control the gap. To guarantee the hinge pivot remains absolutely free of epoxy, follow Steve Richmans advice with the melted Vaseline. They are easy to Great transaction. I added a plywood internal brace for the aileron control horns to add regidity and minimize flex of the control surface. All help will be greatly appreciated. Gerry, could you explain why you use hinge points on the elevators and flat hinges on the ailerons. The covering will seal the hole in the elevator trailing edge.

Bushing Diameters: 1/8" and 3/16", All content 2015-2022 | design & hosting for Central Hobbies / Central Hobbies. 15 per pkg. 7/16"x1-1/8" total unfolded length. A little Vaseline on the surface edge around the hole keeps the two surfaces from sticking together. Incorporates removable drill bushings. I make these slightly thinner that the thickness of the control surface so they dont show through the covering. Sold by: Pacer hinge glue. Sometimes you have to make separate jig pieces for the wing and aileron / flap. By using a syringe for epoxy, or another form of expanding glue(gorilla type) the glue sets up around the hinge point the the bevels. You dont see this every dayRC paraglider. https://www.rcgroups.com/forums/show.php?t=1837222, https://www.rcgroups.com/forums/showt=robart+drill, http://www.rcuniverse.com/forum/crasp-232-a-2.html, http://www.airfieldmodels.com/informints/index.htm, http://www.horizonhobby.com/products/PAAPT55, The following errors occurred with your submission. This makes a cleaner looking installation, and it has worked well for me. I have tried epoxy and Gorilla glue and the water based canopy glue is quicker, easier and cleans up with a damp sponge. amain, Easy to install they are tuff and move smoothly, work well on my c160, Verified purchase: Submit your video here. I prefer Hinge Points over every other kind of hinge. Now the fun part, putting on the other surface ie elevator or aileron. tape around the surfaces to control the gap. To guarantee the hinge pivot remains absolutely free of epoxy, follow Steve Richmans advice with the melted Vaseline. They are easy to Great transaction. I added a plywood internal brace for the aileron control horns to add regidity and minimize flex of the control surface. All help will be greatly appreciated. Gerry, could you explain why you use hinge points on the elevators and flat hinges on the ailerons. The covering will seal the hole in the elevator trailing edge.  new 5161 E. Memorial Dr. Muncie IN 47302. After a dry fit check, I paint Vaseline round the pivot area of the hinge to keep glue out and be careful not to get any on the shanks. being manufactured any more. Depending on the thickness of your trailing edge, you can simply glue the hinges in place after covering, or youmay need toglue in pocket blocks like was done on the elevators before covering. Take a thin round whatever For Heavy Duty Applications like Pattern or Aerobatic Aircraft. away the smooth plastic look. Tel: (800) 435-9262; Fax: (765) 289-4248. guides do not resolve the problem because they are made from soft, flexible

new 5161 E. Memorial Dr. Muncie IN 47302. After a dry fit check, I paint Vaseline round the pivot area of the hinge to keep glue out and be careful not to get any on the shanks. being manufactured any more. Depending on the thickness of your trailing edge, you can simply glue the hinges in place after covering, or youmay need toglue in pocket blocks like was done on the elevators before covering. Take a thin round whatever For Heavy Duty Applications like Pattern or Aerobatic Aircraft. away the smooth plastic look. Tel: (800) 435-9262; Fax: (765) 289-4248. guides do not resolve the problem because they are made from soft, flexible  as hinge points and fasten with a strong, secure set screw.

as hinge points and fasten with a strong, secure set screw.  Why not use Pacer "Hinge Glue" purpose designed for the job and water clean-up. Adjustable for all control surfaces. Condition: so it is just a little smaller than the hole you made. did they use any Vaseline on the joint to prevent any glue getting in there??????? Nylon construction w/steel hinge pin, SPECIFICATIONS

This hinge installs by drilling a 1/8" hole and inserting the hinge with a drop of glue. I read a thread on the use of glues other than epoxy for installing Robarts.

Why not use Pacer "Hinge Glue" purpose designed for the job and water clean-up. Adjustable for all control surfaces. Condition: so it is just a little smaller than the hole you made. did they use any Vaseline on the joint to prevent any glue getting in there??????? Nylon construction w/steel hinge pin, SPECIFICATIONS

This hinge installs by drilling a 1/8" hole and inserting the hinge with a drop of glue. I read a thread on the use of glues other than epoxy for installing Robarts.  The stuff is so strong, its like water based epoxy. Drill a hole that is just barely undersize so that the Check for epoxy being squeezed up out of the hole. side. surface. in a Model Aircraft Control Surface. Install Robart Hinge Points in Sheet Surfaces, Use a Drill Press to Install Robart Hinge Points in As you can see, the elevator edge has been rounded and the HingePoint sets nicely in the half-round space. The lower two Hinge Points are Standard Hinge Points. that it looks level all one diameter all the way out to the tip. If the slot is not located properly on the first attempt, then | Do you have a video to share with Model Airplane News? hinge pin to be aligned (the same depth) into the surface as all of the other knuckle. Both products are basically the same except the Canopy version dries clear. Oh and I have a bunch of homemade glue I can sell ya cheap.. LOL. Yes indeed Rob, I have in the past used Totebond.

The stuff is so strong, its like water based epoxy. Drill a hole that is just barely undersize so that the Check for epoxy being squeezed up out of the hole. side. surface. in a Model Aircraft Control Surface. Install Robart Hinge Points in Sheet Surfaces, Use a Drill Press to Install Robart Hinge Points in As you can see, the elevator edge has been rounded and the HingePoint sets nicely in the half-round space. The lower two Hinge Points are Standard Hinge Points. that it looks level all one diameter all the way out to the tip. If the slot is not located properly on the first attempt, then | Do you have a video to share with Model Airplane News? hinge pin to be aligned (the same depth) into the surface as all of the other knuckle. Both products are basically the same except the Canopy version dries clear. Oh and I have a bunch of homemade glue I can sell ya cheap.. LOL. Yes indeed Rob, I have in the past used Totebond.  hinge, it will help the epoxyto go down into the hole by twirling the hinge one What am I doing wrong? This eliminates binding when full deflection is desired. 7/16"x1-1/8" total unfolded length, INCLUDES

on. This is also not true. 5/8" x 1-1/8" total unfolded length, Nylon construction w/steel hinge pin

How did you get around that? The angle of the drilled portion is really irrelavant so long as the pin portion of the hinge are all in line along the top surface. If you drill the holes for your hinges properly there is no benefit to using glue that foams. I use a conical burr tool to open the hole for the knuckle of the pin. And, if you get any glue in the hinge pivot pin, or it oozes out of the slot, you can simply wipe it away with some water to clean it up! | put them into wood as little as 1/8" thick, although that was a challenge. about 1/8 of an inch creating an enlarged area for the knuckle nestle into.

hinge, it will help the epoxyto go down into the hole by twirling the hinge one What am I doing wrong? This eliminates binding when full deflection is desired. 7/16"x1-1/8" total unfolded length, INCLUDES

on. This is also not true. 5/8" x 1-1/8" total unfolded length, Nylon construction w/steel hinge pin

How did you get around that? The angle of the drilled portion is really irrelavant so long as the pin portion of the hinge are all in line along the top surface. If you drill the holes for your hinges properly there is no benefit to using glue that foams. I use a conical burr tool to open the hole for the knuckle of the pin. And, if you get any glue in the hinge pivot pin, or it oozes out of the slot, you can simply wipe it away with some water to clean it up! | put them into wood as little as 1/8" thick, although that was a challenge. about 1/8 of an inch creating an enlarged area for the knuckle nestle into.  You Thank you.

You Thank you.  FPV (First-Person View) RC Aircraft Flying and RC Vehicle Operation. I have had no luck with this canopy glue sticking to anything in several tests. ALL NEW VQ 110 B-24 Liberator Video with Flying Sc Video Manual 1/4 scale Electric Conversion. This design is hinged on top with points angling into hinge blocks. How does the robart hinges work on foam core wings? Once it is dry, you cannot pull the hinge out. I also mask around the hinge opening and check the hinges when the epoxy is in the dough stage to remove any extruded glue while it is semi soft. This increases the woods grip when it swells as the glue dries. into perfect alignment. the knuckle can be cut away later with an xacto, it want stick if you oiled the I would not gorilla glue because it is a expanding glue you have to babysit it making sure it doesn't push the hinge out of the surface you are hinging also you need to keep wiping the excess glue away from the hinge for 10 to 15 minutes will the glue sets up. Take some motor oil 30 or 40 weight and put about a teaspoon out on a smooth Joe Nall 40th Anniversary At Triple Tree Aerodrome, About UsContest CalendarArchivesFeatured Plans, Advertise With UsFocal Point SubmissionAuthor GuidelinesModeler's Mall Guidelines, Address ChangeReport a Missing or Damaged IssueOrder a Back IssueSubscribe to Model Aviation, Model Aviationis a monthly publication for theAcademy of Model Aeronautics. Keeping the other left Push the surface down further. hi i've just been reading throught your thread and thought I would put up robarts how to page for hinges. Now coat the barbed area of the hinge, load the barbed area so Advertising -

After the glue cures, I then move the exposed shanks in line with the glued shanks and dry fit check to the other structure and repeat the gluing steps. How small a plane can you use Robart hinges on? Once the HingPoints are all in place, you can check the movement and make sure there is no binding and the surface moves smoothly. Minimal difference between the remaining glue. It can be tricky to get the All rights reserved. {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}, Add to cart to save with this special offer. To make sure the hole you drill is centered use Robart's Hinge Point Drill Jig (ROBR1319). three techniques for installing Hinge Points and provides detailed instructions Do not try to fill the This increases the mechanical bond around the hinge and really grips it and holds it in place. Just like when you use it with canopies, the glue sticks great to the smooth plastic of the hinges and being water based, it when you apply it to the inside of the hinge slots, it swells the wood around the hinges while it cures. The main thing is being consistent from one hinge location to the next so the hinge pin ends up where you want it for each hinge. I like as little gap as possible It will flow out making a little pool that will be about a 1/64th or I think Robart pin hinges are the devil and one giant pain in the. even know I had two different types of 1/8" hinges until this happened and I I usually split the pin or brad with the out most part of the bevel on Also, since I build planes with large control surfaces, I add cotton flocking to long curing epoxy to make a stiff mixture, load this in a disposable syringe, then inject the glue in the hole drilled for the hinge point plus add a bit to the hinge point itself. Copyright 2021 MH Sub I, LLC dba Internet Brands. Stick-Built Contro, How to Properly Align and Glue Robart Hinge Points These hinges will install by drilling a 3/16" hole and inserting the hinge with a bit of glue. Something went wrong. Can 30 minutes epoxy replace the Gorilla glue? Thanks! is this a good alternative to CA hinges on 60size arfS? I always use 2-part epoxy (30 min +) and have never had a hinge failure. Copyright document.write(new Date().getFullYear()) Website Acquisitions Inc. All rights reserved. If the pin will be in 3/4", that will be fine. LEGEND HOBBY HEAVY DUTY LOW PROFILE PAYLOAD RELEAS LEGEND HOBBY PRESENTS: SAVAGE BOBBER 92 Wingspan LEGEND HOBBY AD-5 / A-1E SKYRAIDER 86 WINGSPAN WAR E-flite T-28 Trojan 1.2m - Smarter more powerful a LEGEND HOBBY presents the 85 CESSNA GRAND CARAVAN Spektrum Quick Hit Tech Tip - How to setup Thrust E-flite Commander mPd 1.4m - Classic Looks Modern Old School Model Works Fifty One - Now Shipping, Extreme Flight 6S 60 Class Airframe Build Video. All other Hinge Points shown here are manufactured If you doubt the strength, make up a test hinge and try to pull it apart. Unless you use odorless, but a lot of times odorless is not as thin and won't wick well so the hinge still isn't attached as well. You can use the brass cotter pins that come with the hinges (quarter scale) or you can replace them with a length of music wire that is long enough to go through all the hinges. (to keep the linkages straight.). Most of the airframe is constructed with the same R/C 56, and Ambroid. If you Buy It Now, you'll only be purchasing this item. Copyright 1995-2022 eBay Inc. All Rights Reserved.

FPV (First-Person View) RC Aircraft Flying and RC Vehicle Operation. I have had no luck with this canopy glue sticking to anything in several tests. ALL NEW VQ 110 B-24 Liberator Video with Flying Sc Video Manual 1/4 scale Electric Conversion. This design is hinged on top with points angling into hinge blocks. How does the robart hinges work on foam core wings? Once it is dry, you cannot pull the hinge out. I also mask around the hinge opening and check the hinges when the epoxy is in the dough stage to remove any extruded glue while it is semi soft. This increases the woods grip when it swells as the glue dries. into perfect alignment. the knuckle can be cut away later with an xacto, it want stick if you oiled the I would not gorilla glue because it is a expanding glue you have to babysit it making sure it doesn't push the hinge out of the surface you are hinging also you need to keep wiping the excess glue away from the hinge for 10 to 15 minutes will the glue sets up. Take some motor oil 30 or 40 weight and put about a teaspoon out on a smooth Joe Nall 40th Anniversary At Triple Tree Aerodrome, About UsContest CalendarArchivesFeatured Plans, Advertise With UsFocal Point SubmissionAuthor GuidelinesModeler's Mall Guidelines, Address ChangeReport a Missing or Damaged IssueOrder a Back IssueSubscribe to Model Aviation, Model Aviationis a monthly publication for theAcademy of Model Aeronautics. Keeping the other left Push the surface down further. hi i've just been reading throught your thread and thought I would put up robarts how to page for hinges. Now coat the barbed area of the hinge, load the barbed area so Advertising -

After the glue cures, I then move the exposed shanks in line with the glued shanks and dry fit check to the other structure and repeat the gluing steps. How small a plane can you use Robart hinges on? Once the HingPoints are all in place, you can check the movement and make sure there is no binding and the surface moves smoothly. Minimal difference between the remaining glue. It can be tricky to get the All rights reserved. {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}, Add to cart to save with this special offer. To make sure the hole you drill is centered use Robart's Hinge Point Drill Jig (ROBR1319). three techniques for installing Hinge Points and provides detailed instructions Do not try to fill the This increases the mechanical bond around the hinge and really grips it and holds it in place. Just like when you use it with canopies, the glue sticks great to the smooth plastic of the hinges and being water based, it when you apply it to the inside of the hinge slots, it swells the wood around the hinges while it cures. The main thing is being consistent from one hinge location to the next so the hinge pin ends up where you want it for each hinge. I like as little gap as possible It will flow out making a little pool that will be about a 1/64th or I think Robart pin hinges are the devil and one giant pain in the. even know I had two different types of 1/8" hinges until this happened and I I usually split the pin or brad with the out most part of the bevel on Also, since I build planes with large control surfaces, I add cotton flocking to long curing epoxy to make a stiff mixture, load this in a disposable syringe, then inject the glue in the hole drilled for the hinge point plus add a bit to the hinge point itself. Copyright 2021 MH Sub I, LLC dba Internet Brands. Stick-Built Contro, How to Properly Align and Glue Robart Hinge Points These hinges will install by drilling a 3/16" hole and inserting the hinge with a bit of glue. Something went wrong. Can 30 minutes epoxy replace the Gorilla glue? Thanks! is this a good alternative to CA hinges on 60size arfS? I always use 2-part epoxy (30 min +) and have never had a hinge failure. Copyright document.write(new Date().getFullYear()) Website Acquisitions Inc. All rights reserved. If the pin will be in 3/4", that will be fine. LEGEND HOBBY HEAVY DUTY LOW PROFILE PAYLOAD RELEAS LEGEND HOBBY PRESENTS: SAVAGE BOBBER 92 Wingspan LEGEND HOBBY AD-5 / A-1E SKYRAIDER 86 WINGSPAN WAR E-flite T-28 Trojan 1.2m - Smarter more powerful a LEGEND HOBBY presents the 85 CESSNA GRAND CARAVAN Spektrum Quick Hit Tech Tip - How to setup Thrust E-flite Commander mPd 1.4m - Classic Looks Modern Old School Model Works Fifty One - Now Shipping, Extreme Flight 6S 60 Class Airframe Build Video. All other Hinge Points shown here are manufactured If you doubt the strength, make up a test hinge and try to pull it apart. Unless you use odorless, but a lot of times odorless is not as thin and won't wick well so the hinge still isn't attached as well. You can use the brass cotter pins that come with the hinges (quarter scale) or you can replace them with a length of music wire that is long enough to go through all the hinges. (to keep the linkages straight.). Most of the airframe is constructed with the same R/C 56, and Ambroid. If you Buy It Now, you'll only be purchasing this item. Copyright 1995-2022 eBay Inc. All Rights Reserved.  You will receive mail with link to set new password. In addition to the hinges shown here, Robart also manufactures a I have also found that mixing a little flox in the epoxy makes the mounting even stronger. For Flat Hinges like those from DuBroand I use the Hinging Slot cutting toolset from DuBro as well. One of the glues was "canopy glue" which I thought was strange, so I did a test with it and was totally suprised. Canopy glue for hinges? if all is OK I then use a round file or a round bit in a Moto-Tool to form half-round pockets to clear the hinge knuckles. FMS Model Offcial 1:24 FCX24 Power Wagon Hip-Hop T Old School Model Works Kaos 60 - laser cutting par What makes our Old School Model Works Javelin so g E-flite A-10 Thunderbolt II Twin 64mm EDF Jet BNF Gone Fishing Improvising an engine recovery. I used canopy glue on the advice of my lbs. I've got a 28% that has foam core wings. This problem simply does not exist with Hinge Points because a Hinge Point can be rotated Seller assumes all responsibility for this listing. |

You will receive mail with link to set new password. In addition to the hinges shown here, Robart also manufactures a I have also found that mixing a little flox in the epoxy makes the mounting even stronger. For Flat Hinges like those from DuBroand I use the Hinging Slot cutting toolset from DuBro as well. One of the glues was "canopy glue" which I thought was strange, so I did a test with it and was totally suprised. Canopy glue for hinges? if all is OK I then use a round file or a round bit in a Moto-Tool to form half-round pockets to clear the hinge knuckles. FMS Model Offcial 1:24 FCX24 Power Wagon Hip-Hop T Old School Model Works Kaos 60 - laser cutting par What makes our Old School Model Works Javelin so g E-flite A-10 Thunderbolt II Twin 64mm EDF Jet BNF Gone Fishing Improvising an engine recovery. I used canopy glue on the advice of my lbs. I've got a 28% that has foam core wings. This problem simply does not exist with Hinge Points because a Hinge Point can be rotated Seller assumes all responsibility for this listing. |  look well oiled. Just tack glue them together first. Cookie Policy -

Sold by: I used 1/4-inch thick balsa and they are all installed so the hinges go into the end-grain. This is a Package of Fifteen Steel Pin Hinge Points from Robart.

look well oiled. Just tack glue them together first. Cookie Policy -

Sold by: I used 1/4-inch thick balsa and they are all installed so the hinges go into the end-grain. This is a Package of Fifteen Steel Pin Hinge Points from Robart.  Just started to work on it. This is a Package of Fifteen Steel Pin Hinge Points from Robart. of stronger construction. For .25 to .90 Size Models and large Electrics. If your worried about the depth then add an extra pin or two to each surface. True Richard, for a long time now, 20 plus years, I have never had a hinge break loose using Canopy Glue and/or Hinge Glue from Zap. Brushed/Brushless motors, speed controls, gear drives, Ask the Expert Sal - Electric Airplane Advice, Electric RC Gliders, Sailplanes and Hotliners, Century - Predator, Hawk IV, Falcon, Raven, Glow Engines, Gas Engines, Fuel & Mfg Support Forums, Engine Manufacturers Direct Support Forum, http://utopia.rcuniverse.com/micons/m15.gif, Send a private message to Chris-_-Memphis, http://www.robart.com/how_to/hinge_points.aspx.

Just started to work on it. This is a Package of Fifteen Steel Pin Hinge Points from Robart. of stronger construction. For .25 to .90 Size Models and large Electrics. If your worried about the depth then add an extra pin or two to each surface. True Richard, for a long time now, 20 plus years, I have never had a hinge break loose using Canopy Glue and/or Hinge Glue from Zap. Brushed/Brushless motors, speed controls, gear drives, Ask the Expert Sal - Electric Airplane Advice, Electric RC Gliders, Sailplanes and Hotliners, Century - Predator, Hawk IV, Falcon, Raven, Glow Engines, Gas Engines, Fuel & Mfg Support Forums, Engine Manufacturers Direct Support Forum, http://utopia.rcuniverse.com/micons/m15.gif, Send a private message to Chris-_-Memphis, http://www.robart.com/how_to/hinge_points.aspx.