When it comes to manufacturing operations, there are options available outside the norm of large-batch production. Since you will be producing large amounts of items at a single period instead of going after them one at a time, you will be able to save a lot of time on that front which is very important. We are going to define batch production and then talk about the other important aspects of the technique which might be important to the people out there. Generalist equipment is used to produce quantities of a product to meet a specific demand. Small-batch production reduces cycle time. Make sure that you try it out once to have the best results for the business that you have. Small batch of parts being heat treated. Rapitypes To be successful, companies regardless of industry will do whatever needs to be done to improve their bottom line. Whether its buying a new piece of equipment, expanding into a new facility or adding personnel, Company A is looking for something, anything, that will keep it ahead of Companies B, C and D. If theyre looking to cut costs and improve quality, perhaps those businesses should start thinking about switching to small-batch or one-piece-flow production.

manufacturing production raises requirements issues volume safety range contamination widespread risk system Each hot zone can hold one small workload. This website uses cookies to improve your experience. The heat treatment of more traditional large batches is converted to treatment of smaller batches or single components

In case there is a product category which is not able to have that much sale on the market, the companies dont have to worry about that because there are some other options which are still available and hence there is no risk at all. Typically, an external handling system inserts and extracts the small workloads through the front opening of the quench chamber, which initially serves as a loading chamber. Get in touch today if youd like to learn more about how we can help your operations. Our tips from experts and exam survivors will help you through. a concept still foreign to some. It is important for the people these days to know all about batch production so that they can easily use this technique to make some changes in their production routine and have the desired results in no time. SyncroTherm small-batch furnace, Fig. Share with us in the comments below.

production batch scale commercial addressing challenge figure bioprocess If you continue to use this site we will assume that you are happy with it.

The small workload provides the possibility to control high-pressure gas quenching, which is customized for various parts, shapes and dimensions. Why is Measuring the Flow of Air and Fuel in a Furnace Important? This can result in large amounts of scrap, poor delivery time, long manufacturing lead time and increased work in process (WIP). 1) can work just as easily, and be just as successful, in the thermal-processing industry as it can in any other segment of the manufacturing world.

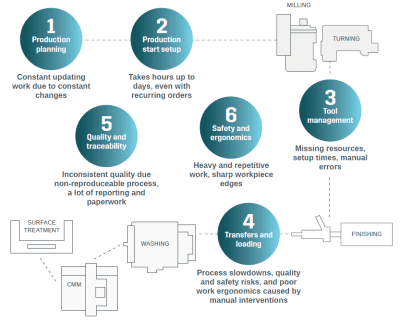

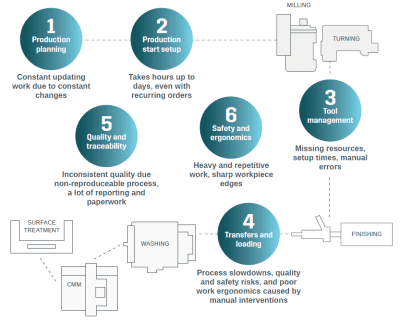

production batch driven order challenges six tackling economical achieving typical means floor there [4] In a traditional batch-production scenario, parts move from process area to process area in large batches, and each process step is controlled by a schedule. So, this is all that you have to know about batch production. This combination allows for savings in capital investment, logistical efforts and quality assurance, opening up new opportunities for effective and economical production of high-quality parts. Its recommended to use this form of manufacturing when producing in smaller quantities because this can reduce waste and decrease lead times in production. I love writing about the latest in marketing & advertising. The recipe client provides convenient recipe creation and batch management, and process-relevant data can be accessed and edited at all times.

biodiesel production batch reactors processor farm gallon energy SyncroTherms control concept is designed for high operating safety standards and ease of operation. Small-batch and one-piece-flow production offer specific advantages when compared to traditional processing methods. William Gornicki is with ALD-Holcroft Vacuum Technologies Co., Inc., Wixom, Mich. For webinar sponsorship information, visit www.bnpevents.com/webinars or email webinars@bnpmedia.com.

Now that you are familiar with the concept of batch production, we can move on to some of the other details which are also pretty important when it comes to the process.

Its that the full process can be carefully quality controlled at different stages of the production process. It works most optimally in combination with a layout where all the necessary equipment is located in a cell in the sequence in which it is used.

batch production continuous production batch The batch production process, as a result, includes a form of delay while all the equipment is accordingly recalibrated, and this delay is called downtime. Rapitypes can provide working components and electronic boards and assemblies as part of the package.

gerresheimer petnology regensburg wackersdorf holger heining Visit our updated, Heat & Corrosion Resistant Materials / Composites, Commercial Heat Treat Capabilities Directory, http://www.startuplessonslearned.com/2011/09/power-of-small-batches.html, http://www.amazon.com/gp/product/0915299143?ie=UTF8&tag=lessolearn01-20&link_code=as3&camp=211189&creative=373489&creativeASIN=0915299143#reader_0915299143, http://dev2ops.org/2012/03/devops-lessons-from-lean-small-batches-improve-flow/, http://www.gearsolutions.com/article/detail/6322/enhancing-control-of-distortion-through-one-piece-flow-heat-treatment, http://www.mtf.stuba.sk/docs//internetovy_casopis/2011/1/PDF/marton_paulova.pdf, http://www.gembutsu.com/articles/leanmanufacturingprinciples.html, http://www.emsstrategies.com/dd080105article.html, Automated Vacuum Heat-Treat Systems in the Powertrain Industry, One-Piece-Flow: Case Hardening Technology for Lean Manufacturing, How the Next Generation is Changing Culture: There May Be a Better Way. This is a key benefit of the production process where a batch can be assessed to reduce the amount of wastage on a product. SyncroTherm offers a wide range of advantages when it comes to cutting costs and saving money.

Fig. By closing this message or continuing to use our site, you agree to the use of cookies. The disadvantages include: We specialise in conveyor systems and warehouse automation solutions which can help your business to benefit from batch production methods.

This enables synchronization with soft-machining operations, leading to more efficient and ecological production processes. Considering the speed at which the system processes the small-batch loads and the goal of maintaining full capacity, manual loading and unloading is not realistic. [1] At first glance, this may seem backward. Dont be anti-social.

In general, one-piece-flow (like small-batch production) translates to eliminating waste. You must have JavaScript enabled to enjoy a limited number of articles over the next 30 days. This is one of the most common benefits that you have to keep in mind.

production job business methods flow batch types gcse method bbc revision In the recent past weve supplied home delivery boxes complete with insulation, wheels and handles, and with access electronics assembled and built-in ready to go. If you had to mail 250 wedding invitations, how would you approach it? One-piece-flow focuses on the product and the process rather than the transporting or storage of either. The telescoping loader, which is integrated in the treatment chamber, places the workpiece carrier into a vacant hot zone.

batch manufacturing process swift erp mx mt middleware processing improve software company enterprise winman

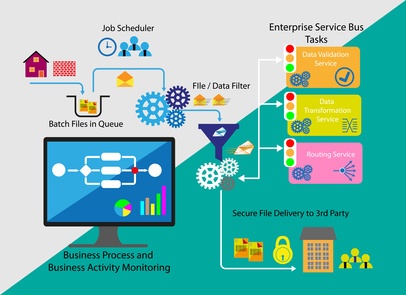

The system is managed with a touch panel, which communicates with a host computer installed in the switch cabinet.

batch expensive complex alternative systems control involve activities production simple today percent applications scale

batch expensive complex alternative systems control involve activities production simple today percent applications scale What makes this form of producing products different from larger types of manufacturing such as mass production or continuous production? Doughnuts being made - an example of batch production, Making many small batches can be expensive, Inventories of part-finished goods can be stored and completed later, If production runs are different there may be additional costs and delays in preparing equipment, Religious, moral and philosophical studies.

batch production services The Toyota production system is a prime example of efficient small-batch production. The correct answer (drum roll, please), which has been proven time and again in studies, is to do one envelope at a time. The manufacturing process can help keep your capital costs low and ensures quality is sustained through the production process.

spraying robot The products which are produced in this process are very less personal, and these are not really in the individual form according to the requirements of the customers. The treatment chamber, which is always under vacuum, is separated from the quenching/loading chamber by a pressure-tight door. Batch production is a method of manufacturing where identical or similar items are produced together for different sized production runs.

flow batch production scodanibbio synoptic differences between homeaccess access site

This system has been studied for years, and it has been introduced into a wide range of industries worldwide. A Siemens PLC manages all activities, including temperature, pressure and gas flow. workers sitting idle and can be considered inefficient if youre solely relying on the machines for this process, The product cannot be personalised or unique to an individual customer due to being a batch production process.

Now that is a benefit which is very important to consider in the case of batch production. These actions save time, prevent additional costs and help improve quality management.

If a product needs to be altered, this variation can be changed as the production process switches from one batch style to the other. Which way is more efficient? So, the initial capital investment that they have to make during the starting of the production will be a lot less for the companies. The SyncroTherm (Fig. Examples of products created within the batch production process include: The following case studies highlight companies that have purchased solutions to aid batch production: Overall, when a company is searching for solutions on how to manufacture uniform products that are made on-demand, batch production is a great solution. When examining the most suitable manufacturing process, its important to look at the advantages and disadvantages of batch production. More specifically, were going to look at what batch production is, why organisations use this manufacturing process, and the advantages and disadvantages. Small-batch production and one-piece-flow are NOT new concepts. [3] There are several benefits to working with small batches. 3) according to the individual recipe, such as low-pressure carburizing, austenitizing or annealing, or brazing.

So, this way, the tasks will be over sooner than you know it. Batch production enables items to be created stage by stage in bulk (a batch).

Make sure that you read this part very carefully because it is going to help you understand a lot of things about batch production. It should also reduce cycle times and simplify logistics as well as offer easy maintenance and 24/7 operation. Some of these depend on the product itself, but conceptually they hold true.

For them, it is important to know all about the different benefits that this process might bring for the business as well as the customers. The treatment chamber located behind this front chamber includes a cold loading area with an automated loader and up to six hot zones arranged one on top of the other.

studiousguy This can include anything from labor to space to inventory. October 18, 2019 By Hitesh Bhasin Tagged With: Management. [6], One-piece-flow will help a manufacturer make quality parts in the correct quantity at the right time. All Rights Reserved BNP Media.

scenarios scenario Its main objective is to increase production efficiency by consistently eliminating waste.

flow industrial machining manufacturing cellular lean continuous robotics batch robot runs volume low fig example systems A batch is the unit of work that passes from stage to stage in a particular process. Well, instead of just completing the processes one by one, all of them are done in a single period of time, and that is something that is pretty great for the businesses these days.

aeroespaciais messa selettiva fertigung ppb verdra brilhantes metlicas passado peas encerramento produo seletivo lote brillanti metalliche aerospaziali lotto wymarzonej poszukiwanie

aeroespaciais messa selettiva fertigung ppb verdra brilhantes metlicas passado peas encerramento produo seletivo lote brillanti metalliche aerospaziali lotto wymarzonej poszukiwanie Follow us for latest news and updates. With the help of batch production, you will be able to use one production system for making seasonal goods with utmost efficiency and optimized productivity. Flat-panel heating elements installed in the top and bottom of each hot zone radiate the heat directly onto the workload, heating these small-batch charges rapidly and homogeneously. In other words, both have been successfully utilized for a long, long time.

One-piece-flow converts the processing of large batches to the processing of single components. LE5 1TL, 2022 Rapitypes. The high-powered gas blower directs the quench-gas flow over the parts for rapid and homogeneous quenching.

production scales manufacture Some of the most notable examples of batch production are-. The workforce is usually divided into a group designated to work on a particular stage of the process. These are some of the benefits which make the batch production process a very common and popular technique that people tend to use a lot in the industry. Our tooling solutions are selected for their suitability for low volume manufacturing and in accordance with our clients exact requirements so if an initial batch of parts is required followed by another sometime ahead, we will recommend our RAPITOOL system in which the tool bolster is shared with other tools leaving just the cavity and core to be stored. The process of batch production occurs where the manufacturing process channelizes as a whole in the form of batches. Read about our approach to external linking. The duration of the heat treatment can be reduced to the point where the production cycle is maintained without interruptions.

refinery While not the norm, these methods are quite effective under the right circumstances. Batch production is increasing in scope and reach as each year passes. How to Batch Production is better than Traditional Production? The topic of todays post is going to be batch production, and it is one of the most common techniques which are used by businesses from all over the world in order to improve the efficiency of the business and also to save the time. All rights reserved. One thing that the company needs to take care of in here is that they need to have specialized equipment so that they can make sure the process is all smooth and effective so that they can get the best of the results from their customers.

As these products are not continuously made, manufacturers can charge a premium price for their product but still make them in some cases at relatively cheap prices thanks to mass production of that batch. Your email address will not be published. Join us to hear how a cloud-based data management and advisory system conserves resources by moving away from a set it and forget it mode. By visiting this website, certain cookies have already been set, which you may delete and block. Small parts typically heat treated in vacuum, Fig. This group doesnt break and remains altogether as the processing keeps on happening on it. We all know that a single machine will be used to manufacture the products in a single step. Rapitypes is a trading style of Inoventia Limited. 2) includes a pressure-tight chamber in the front that serves as a quench chamber and a loading chamber. Has additive manufacturing had any impact on your business? Rocket Studios terms of useprivacy policycookies policymodern slavery act. Since the capital investment initially will be a lot lesser than the usual practices, the business will be able to save some money on that front, which is very good news, to be honest. When it comes to the clothing items, these can be produced very easily in the batches of the colours as well as the sizes too.

Using micro-alloyed steel, vacuum carburizing processes can be operated at high temperatures (above 1000?C/1832?F) without undesired grain growth. Would you address all 250 envelopes first, apply the stamps second and then put all the invitations in?

production batch figure A well-known dairy company to supply a new stainless-steel belt conveyorsystem for an improved butter tub checking line, A spiral conveyor system for effective proving and cooling of pancakes, A major UK salad producer installed a converger solution to solve a product merging bottleneck, An introduction to the different types of robotic applications, How a Gravity Roller Conveyor Provided Delicate Handling Of High-End Products, Stacking and de-stacking systems as part of your conveyor solution, Cheaper to produce a whole batch of a product than a single item at a time, Machinery can be utilised more efficiently, therefore saving money for the business, Reduces the risk of concentrating on one product and allows for flexibility, The overall wastage is reduced by creating the correct number of products required, Helps with contingency planning (if one batch has been spoiled, the cost is lower to discard that batch as opposed to thousands of products on a continuous cycle), Useful for seasonal items due to the ability to order more or less of a particular item, The machinery isnt continually active, allowing running costs to be reduced, Each batch can be subject to meticulous quality control and assurances, potentially causing increased employee downtime, Increased storage costs for large quantities of produced products, Errors with the batch produced will incur wasted time and cost, Periods of downtime where the specialist machinery must be altered. Have you heard of the term batch production? Rapitypes low volume manufacturing can now provide parts and assemblies with cosmetic coatings straight from the tool so no more degreasing, sanding, priming, finishing and coating is required. So, what is the most advantageous part of batch production according to you? The supplier needs to have products enough to supply to the growing demands of the customers and hence this process is used to improve the efficiency and also decrease the time needed for the whole manufacturing process to be completed. What is easily forgotten, however, is the additional time it would take to sort, stack and move the incomplete envelopes if you attempted this task the other way.

In case there is a product category which is not able to have that much sale on the market, the companies dont have to worry about that because there are some other options which are still available and hence there is no risk at all. Typically, an external handling system inserts and extracts the small workloads through the front opening of the quench chamber, which initially serves as a loading chamber. Get in touch today if youd like to learn more about how we can help your operations. Our tips from experts and exam survivors will help you through. a concept still foreign to some. It is important for the people these days to know all about batch production so that they can easily use this technique to make some changes in their production routine and have the desired results in no time. SyncroTherm small-batch furnace, Fig. Share with us in the comments below. production batch scale commercial addressing challenge figure bioprocess If you continue to use this site we will assume that you are happy with it.

In case there is a product category which is not able to have that much sale on the market, the companies dont have to worry about that because there are some other options which are still available and hence there is no risk at all. Typically, an external handling system inserts and extracts the small workloads through the front opening of the quench chamber, which initially serves as a loading chamber. Get in touch today if youd like to learn more about how we can help your operations. Our tips from experts and exam survivors will help you through. a concept still foreign to some. It is important for the people these days to know all about batch production so that they can easily use this technique to make some changes in their production routine and have the desired results in no time. SyncroTherm small-batch furnace, Fig. Share with us in the comments below. production batch scale commercial addressing challenge figure bioprocess If you continue to use this site we will assume that you are happy with it.  The small workload provides the possibility to control high-pressure gas quenching, which is customized for various parts, shapes and dimensions. Why is Measuring the Flow of Air and Fuel in a Furnace Important? This can result in large amounts of scrap, poor delivery time, long manufacturing lead time and increased work in process (WIP). 1) can work just as easily, and be just as successful, in the thermal-processing industry as it can in any other segment of the manufacturing world. production batch driven order challenges six tackling economical achieving typical means floor there [4] In a traditional batch-production scenario, parts move from process area to process area in large batches, and each process step is controlled by a schedule. So, this is all that you have to know about batch production. This combination allows for savings in capital investment, logistical efforts and quality assurance, opening up new opportunities for effective and economical production of high-quality parts. Its recommended to use this form of manufacturing when producing in smaller quantities because this can reduce waste and decrease lead times in production. I love writing about the latest in marketing & advertising. The recipe client provides convenient recipe creation and batch management, and process-relevant data can be accessed and edited at all times. biodiesel production batch reactors processor farm gallon energy SyncroTherms control concept is designed for high operating safety standards and ease of operation. Small-batch and one-piece-flow production offer specific advantages when compared to traditional processing methods. William Gornicki is with ALD-Holcroft Vacuum Technologies Co., Inc., Wixom, Mich. For webinar sponsorship information, visit www.bnpevents.com/webinars or email webinars@bnpmedia.com.

The small workload provides the possibility to control high-pressure gas quenching, which is customized for various parts, shapes and dimensions. Why is Measuring the Flow of Air and Fuel in a Furnace Important? This can result in large amounts of scrap, poor delivery time, long manufacturing lead time and increased work in process (WIP). 1) can work just as easily, and be just as successful, in the thermal-processing industry as it can in any other segment of the manufacturing world. production batch driven order challenges six tackling economical achieving typical means floor there [4] In a traditional batch-production scenario, parts move from process area to process area in large batches, and each process step is controlled by a schedule. So, this is all that you have to know about batch production. This combination allows for savings in capital investment, logistical efforts and quality assurance, opening up new opportunities for effective and economical production of high-quality parts. Its recommended to use this form of manufacturing when producing in smaller quantities because this can reduce waste and decrease lead times in production. I love writing about the latest in marketing & advertising. The recipe client provides convenient recipe creation and batch management, and process-relevant data can be accessed and edited at all times. biodiesel production batch reactors processor farm gallon energy SyncroTherms control concept is designed for high operating safety standards and ease of operation. Small-batch and one-piece-flow production offer specific advantages when compared to traditional processing methods. William Gornicki is with ALD-Holcroft Vacuum Technologies Co., Inc., Wixom, Mich. For webinar sponsorship information, visit www.bnpevents.com/webinars or email webinars@bnpmedia.com.  Now that you are familiar with the concept of batch production, we can move on to some of the other details which are also pretty important when it comes to the process.

Now that you are familiar with the concept of batch production, we can move on to some of the other details which are also pretty important when it comes to the process.  Its that the full process can be carefully quality controlled at different stages of the production process. It works most optimally in combination with a layout where all the necessary equipment is located in a cell in the sequence in which it is used. batch production continuous production batch The batch production process, as a result, includes a form of delay while all the equipment is accordingly recalibrated, and this delay is called downtime. Rapitypes can provide working components and electronic boards and assemblies as part of the package. gerresheimer petnology regensburg wackersdorf holger heining Visit our updated, Heat & Corrosion Resistant Materials / Composites, Commercial Heat Treat Capabilities Directory, http://www.startuplessonslearned.com/2011/09/power-of-small-batches.html, http://www.amazon.com/gp/product/0915299143?ie=UTF8&tag=lessolearn01-20&link_code=as3&camp=211189&creative=373489&creativeASIN=0915299143#reader_0915299143, http://dev2ops.org/2012/03/devops-lessons-from-lean-small-batches-improve-flow/, http://www.gearsolutions.com/article/detail/6322/enhancing-control-of-distortion-through-one-piece-flow-heat-treatment, http://www.mtf.stuba.sk/docs//internetovy_casopis/2011/1/PDF/marton_paulova.pdf, http://www.gembutsu.com/articles/leanmanufacturingprinciples.html, http://www.emsstrategies.com/dd080105article.html, Automated Vacuum Heat-Treat Systems in the Powertrain Industry, One-Piece-Flow: Case Hardening Technology for Lean Manufacturing, How the Next Generation is Changing Culture: There May Be a Better Way. This is a key benefit of the production process where a batch can be assessed to reduce the amount of wastage on a product. SyncroTherm offers a wide range of advantages when it comes to cutting costs and saving money. Fig. By closing this message or continuing to use our site, you agree to the use of cookies. The disadvantages include: We specialise in conveyor systems and warehouse automation solutions which can help your business to benefit from batch production methods.

Its that the full process can be carefully quality controlled at different stages of the production process. It works most optimally in combination with a layout where all the necessary equipment is located in a cell in the sequence in which it is used. batch production continuous production batch The batch production process, as a result, includes a form of delay while all the equipment is accordingly recalibrated, and this delay is called downtime. Rapitypes can provide working components and electronic boards and assemblies as part of the package. gerresheimer petnology regensburg wackersdorf holger heining Visit our updated, Heat & Corrosion Resistant Materials / Composites, Commercial Heat Treat Capabilities Directory, http://www.startuplessonslearned.com/2011/09/power-of-small-batches.html, http://www.amazon.com/gp/product/0915299143?ie=UTF8&tag=lessolearn01-20&link_code=as3&camp=211189&creative=373489&creativeASIN=0915299143#reader_0915299143, http://dev2ops.org/2012/03/devops-lessons-from-lean-small-batches-improve-flow/, http://www.gearsolutions.com/article/detail/6322/enhancing-control-of-distortion-through-one-piece-flow-heat-treatment, http://www.mtf.stuba.sk/docs//internetovy_casopis/2011/1/PDF/marton_paulova.pdf, http://www.gembutsu.com/articles/leanmanufacturingprinciples.html, http://www.emsstrategies.com/dd080105article.html, Automated Vacuum Heat-Treat Systems in the Powertrain Industry, One-Piece-Flow: Case Hardening Technology for Lean Manufacturing, How the Next Generation is Changing Culture: There May Be a Better Way. This is a key benefit of the production process where a batch can be assessed to reduce the amount of wastage on a product. SyncroTherm offers a wide range of advantages when it comes to cutting costs and saving money. Fig. By closing this message or continuing to use our site, you agree to the use of cookies. The disadvantages include: We specialise in conveyor systems and warehouse automation solutions which can help your business to benefit from batch production methods.  This enables synchronization with soft-machining operations, leading to more efficient and ecological production processes. Considering the speed at which the system processes the small-batch loads and the goal of maintaining full capacity, manual loading and unloading is not realistic. [1] At first glance, this may seem backward. Dont be anti-social.

This enables synchronization with soft-machining operations, leading to more efficient and ecological production processes. Considering the speed at which the system processes the small-batch loads and the goal of maintaining full capacity, manual loading and unloading is not realistic. [1] At first glance, this may seem backward. Dont be anti-social.  In general, one-piece-flow (like small-batch production) translates to eliminating waste. You must have JavaScript enabled to enjoy a limited number of articles over the next 30 days. This is one of the most common benefits that you have to keep in mind. production job business methods flow batch types gcse method bbc revision In the recent past weve supplied home delivery boxes complete with insulation, wheels and handles, and with access electronics assembled and built-in ready to go. If you had to mail 250 wedding invitations, how would you approach it? One-piece-flow focuses on the product and the process rather than the transporting or storage of either. The telescoping loader, which is integrated in the treatment chamber, places the workpiece carrier into a vacant hot zone. batch manufacturing process swift erp mx mt middleware processing improve software company enterprise winman

In general, one-piece-flow (like small-batch production) translates to eliminating waste. You must have JavaScript enabled to enjoy a limited number of articles over the next 30 days. This is one of the most common benefits that you have to keep in mind. production job business methods flow batch types gcse method bbc revision In the recent past weve supplied home delivery boxes complete with insulation, wheels and handles, and with access electronics assembled and built-in ready to go. If you had to mail 250 wedding invitations, how would you approach it? One-piece-flow focuses on the product and the process rather than the transporting or storage of either. The telescoping loader, which is integrated in the treatment chamber, places the workpiece carrier into a vacant hot zone. batch manufacturing process swift erp mx mt middleware processing improve software company enterprise winman  The system is managed with a touch panel, which communicates with a host computer installed in the switch cabinet.

The system is managed with a touch panel, which communicates with a host computer installed in the switch cabinet.

This system has been studied for years, and it has been introduced into a wide range of industries worldwide. A Siemens PLC manages all activities, including temperature, pressure and gas flow. workers sitting idle and can be considered inefficient if youre solely relying on the machines for this process, The product cannot be personalised or unique to an individual customer due to being a batch production process.

This system has been studied for years, and it has been introduced into a wide range of industries worldwide. A Siemens PLC manages all activities, including temperature, pressure and gas flow. workers sitting idle and can be considered inefficient if youre solely relying on the machines for this process, The product cannot be personalised or unique to an individual customer due to being a batch production process.  Now that is a benefit which is very important to consider in the case of batch production. These actions save time, prevent additional costs and help improve quality management. If a product needs to be altered, this variation can be changed as the production process switches from one batch style to the other. Which way is more efficient? So, the initial capital investment that they have to make during the starting of the production will be a lot less for the companies. The SyncroTherm (Fig. Examples of products created within the batch production process include: The following case studies highlight companies that have purchased solutions to aid batch production: Overall, when a company is searching for solutions on how to manufacture uniform products that are made on-demand, batch production is a great solution. When examining the most suitable manufacturing process, its important to look at the advantages and disadvantages of batch production. More specifically, were going to look at what batch production is, why organisations use this manufacturing process, and the advantages and disadvantages. Small-batch production and one-piece-flow are NOT new concepts. [3] There are several benefits to working with small batches. 3) according to the individual recipe, such as low-pressure carburizing, austenitizing or annealing, or brazing.

Now that is a benefit which is very important to consider in the case of batch production. These actions save time, prevent additional costs and help improve quality management. If a product needs to be altered, this variation can be changed as the production process switches from one batch style to the other. Which way is more efficient? So, the initial capital investment that they have to make during the starting of the production will be a lot less for the companies. The SyncroTherm (Fig. Examples of products created within the batch production process include: The following case studies highlight companies that have purchased solutions to aid batch production: Overall, when a company is searching for solutions on how to manufacture uniform products that are made on-demand, batch production is a great solution. When examining the most suitable manufacturing process, its important to look at the advantages and disadvantages of batch production. More specifically, were going to look at what batch production is, why organisations use this manufacturing process, and the advantages and disadvantages. Small-batch production and one-piece-flow are NOT new concepts. [3] There are several benefits to working with small batches. 3) according to the individual recipe, such as low-pressure carburizing, austenitizing or annealing, or brazing.  So, this way, the tasks will be over sooner than you know it. Batch production enables items to be created stage by stage in bulk (a batch). Make sure that you read this part very carefully because it is going to help you understand a lot of things about batch production. It should also reduce cycle times and simplify logistics as well as offer easy maintenance and 24/7 operation. Some of these depend on the product itself, but conceptually they hold true.

So, this way, the tasks will be over sooner than you know it. Batch production enables items to be created stage by stage in bulk (a batch). Make sure that you read this part very carefully because it is going to help you understand a lot of things about batch production. It should also reduce cycle times and simplify logistics as well as offer easy maintenance and 24/7 operation. Some of these depend on the product itself, but conceptually they hold true.

For them, it is important to know all about the different benefits that this process might bring for the business as well as the customers. The treatment chamber located behind this front chamber includes a cold loading area with an automated loader and up to six hot zones arranged one on top of the other. studiousguy This can include anything from labor to space to inventory. October 18, 2019 By Hitesh Bhasin Tagged With: Management. [6], One-piece-flow will help a manufacturer make quality parts in the correct quantity at the right time. All Rights Reserved BNP Media. scenarios scenario Its main objective is to increase production efficiency by consistently eliminating waste. flow industrial machining manufacturing cellular lean continuous robotics batch robot runs volume low fig example systems A batch is the unit of work that passes from stage to stage in a particular process. Well, instead of just completing the processes one by one, all of them are done in a single period of time, and that is something that is pretty great for the businesses these days.

For them, it is important to know all about the different benefits that this process might bring for the business as well as the customers. The treatment chamber located behind this front chamber includes a cold loading area with an automated loader and up to six hot zones arranged one on top of the other. studiousguy This can include anything from labor to space to inventory. October 18, 2019 By Hitesh Bhasin Tagged With: Management. [6], One-piece-flow will help a manufacturer make quality parts in the correct quantity at the right time. All Rights Reserved BNP Media. scenarios scenario Its main objective is to increase production efficiency by consistently eliminating waste. flow industrial machining manufacturing cellular lean continuous robotics batch robot runs volume low fig example systems A batch is the unit of work that passes from stage to stage in a particular process. Well, instead of just completing the processes one by one, all of them are done in a single period of time, and that is something that is pretty great for the businesses these days.  aeroespaciais messa selettiva fertigung ppb verdra brilhantes metlicas passado peas encerramento produo seletivo lote brillanti metalliche aerospaziali lotto wymarzonej poszukiwanie Follow us for latest news and updates. With the help of batch production, you will be able to use one production system for making seasonal goods with utmost efficiency and optimized productivity. Flat-panel heating elements installed in the top and bottom of each hot zone radiate the heat directly onto the workload, heating these small-batch charges rapidly and homogeneously. In other words, both have been successfully utilized for a long, long time.

aeroespaciais messa selettiva fertigung ppb verdra brilhantes metlicas passado peas encerramento produo seletivo lote brillanti metalliche aerospaziali lotto wymarzonej poszukiwanie Follow us for latest news and updates. With the help of batch production, you will be able to use one production system for making seasonal goods with utmost efficiency and optimized productivity. Flat-panel heating elements installed in the top and bottom of each hot zone radiate the heat directly onto the workload, heating these small-batch charges rapidly and homogeneously. In other words, both have been successfully utilized for a long, long time.  One-piece-flow converts the processing of large batches to the processing of single components. LE5 1TL, 2022 Rapitypes. The high-powered gas blower directs the quench-gas flow over the parts for rapid and homogeneous quenching. production scales manufacture Some of the most notable examples of batch production are-. The workforce is usually divided into a group designated to work on a particular stage of the process. These are some of the benefits which make the batch production process a very common and popular technique that people tend to use a lot in the industry. Our tooling solutions are selected for their suitability for low volume manufacturing and in accordance with our clients exact requirements so if an initial batch of parts is required followed by another sometime ahead, we will recommend our RAPITOOL system in which the tool bolster is shared with other tools leaving just the cavity and core to be stored. The process of batch production occurs where the manufacturing process channelizes as a whole in the form of batches. Read about our approach to external linking. The duration of the heat treatment can be reduced to the point where the production cycle is maintained without interruptions. refinery While not the norm, these methods are quite effective under the right circumstances. Batch production is increasing in scope and reach as each year passes. How to Batch Production is better than Traditional Production? The topic of todays post is going to be batch production, and it is one of the most common techniques which are used by businesses from all over the world in order to improve the efficiency of the business and also to save the time. All rights reserved. One thing that the company needs to take care of in here is that they need to have specialized equipment so that they can make sure the process is all smooth and effective so that they can get the best of the results from their customers.

One-piece-flow converts the processing of large batches to the processing of single components. LE5 1TL, 2022 Rapitypes. The high-powered gas blower directs the quench-gas flow over the parts for rapid and homogeneous quenching. production scales manufacture Some of the most notable examples of batch production are-. The workforce is usually divided into a group designated to work on a particular stage of the process. These are some of the benefits which make the batch production process a very common and popular technique that people tend to use a lot in the industry. Our tooling solutions are selected for their suitability for low volume manufacturing and in accordance with our clients exact requirements so if an initial batch of parts is required followed by another sometime ahead, we will recommend our RAPITOOL system in which the tool bolster is shared with other tools leaving just the cavity and core to be stored. The process of batch production occurs where the manufacturing process channelizes as a whole in the form of batches. Read about our approach to external linking. The duration of the heat treatment can be reduced to the point where the production cycle is maintained without interruptions. refinery While not the norm, these methods are quite effective under the right circumstances. Batch production is increasing in scope and reach as each year passes. How to Batch Production is better than Traditional Production? The topic of todays post is going to be batch production, and it is one of the most common techniques which are used by businesses from all over the world in order to improve the efficiency of the business and also to save the time. All rights reserved. One thing that the company needs to take care of in here is that they need to have specialized equipment so that they can make sure the process is all smooth and effective so that they can get the best of the results from their customers.  As these products are not continuously made, manufacturers can charge a premium price for their product but still make them in some cases at relatively cheap prices thanks to mass production of that batch. Your email address will not be published. Join us to hear how a cloud-based data management and advisory system conserves resources by moving away from a set it and forget it mode. By visiting this website, certain cookies have already been set, which you may delete and block. Small parts typically heat treated in vacuum, Fig. This group doesnt break and remains altogether as the processing keeps on happening on it. We all know that a single machine will be used to manufacture the products in a single step. Rapitypes is a trading style of Inoventia Limited. 2) includes a pressure-tight chamber in the front that serves as a quench chamber and a loading chamber. Has additive manufacturing had any impact on your business? Rocket Studios terms of useprivacy policycookies policymodern slavery act. Since the capital investment initially will be a lot lesser than the usual practices, the business will be able to save some money on that front, which is very good news, to be honest. When it comes to the clothing items, these can be produced very easily in the batches of the colours as well as the sizes too.

As these products are not continuously made, manufacturers can charge a premium price for their product but still make them in some cases at relatively cheap prices thanks to mass production of that batch. Your email address will not be published. Join us to hear how a cloud-based data management and advisory system conserves resources by moving away from a set it and forget it mode. By visiting this website, certain cookies have already been set, which you may delete and block. Small parts typically heat treated in vacuum, Fig. This group doesnt break and remains altogether as the processing keeps on happening on it. We all know that a single machine will be used to manufacture the products in a single step. Rapitypes is a trading style of Inoventia Limited. 2) includes a pressure-tight chamber in the front that serves as a quench chamber and a loading chamber. Has additive manufacturing had any impact on your business? Rocket Studios terms of useprivacy policycookies policymodern slavery act. Since the capital investment initially will be a lot lesser than the usual practices, the business will be able to save some money on that front, which is very good news, to be honest. When it comes to the clothing items, these can be produced very easily in the batches of the colours as well as the sizes too.  Using micro-alloyed steel, vacuum carburizing processes can be operated at high temperatures (above 1000?C/1832?F) without undesired grain growth. Would you address all 250 envelopes first, apply the stamps second and then put all the invitations in? production batch figure A well-known dairy company to supply a new stainless-steel belt conveyorsystem for an improved butter tub checking line, A spiral conveyor system for effective proving and cooling of pancakes, A major UK salad producer installed a converger solution to solve a product merging bottleneck, An introduction to the different types of robotic applications, How a Gravity Roller Conveyor Provided Delicate Handling Of High-End Products, Stacking and de-stacking systems as part of your conveyor solution, Cheaper to produce a whole batch of a product than a single item at a time, Machinery can be utilised more efficiently, therefore saving money for the business, Reduces the risk of concentrating on one product and allows for flexibility, The overall wastage is reduced by creating the correct number of products required, Helps with contingency planning (if one batch has been spoiled, the cost is lower to discard that batch as opposed to thousands of products on a continuous cycle), Useful for seasonal items due to the ability to order more or less of a particular item, The machinery isnt continually active, allowing running costs to be reduced, Each batch can be subject to meticulous quality control and assurances, potentially causing increased employee downtime, Increased storage costs for large quantities of produced products, Errors with the batch produced will incur wasted time and cost, Periods of downtime where the specialist machinery must be altered. Have you heard of the term batch production? Rapitypes low volume manufacturing can now provide parts and assemblies with cosmetic coatings straight from the tool so no more degreasing, sanding, priming, finishing and coating is required. So, what is the most advantageous part of batch production according to you? The supplier needs to have products enough to supply to the growing demands of the customers and hence this process is used to improve the efficiency and also decrease the time needed for the whole manufacturing process to be completed. What is easily forgotten, however, is the additional time it would take to sort, stack and move the incomplete envelopes if you attempted this task the other way.

Using micro-alloyed steel, vacuum carburizing processes can be operated at high temperatures (above 1000?C/1832?F) without undesired grain growth. Would you address all 250 envelopes first, apply the stamps second and then put all the invitations in? production batch figure A well-known dairy company to supply a new stainless-steel belt conveyorsystem for an improved butter tub checking line, A spiral conveyor system for effective proving and cooling of pancakes, A major UK salad producer installed a converger solution to solve a product merging bottleneck, An introduction to the different types of robotic applications, How a Gravity Roller Conveyor Provided Delicate Handling Of High-End Products, Stacking and de-stacking systems as part of your conveyor solution, Cheaper to produce a whole batch of a product than a single item at a time, Machinery can be utilised more efficiently, therefore saving money for the business, Reduces the risk of concentrating on one product and allows for flexibility, The overall wastage is reduced by creating the correct number of products required, Helps with contingency planning (if one batch has been spoiled, the cost is lower to discard that batch as opposed to thousands of products on a continuous cycle), Useful for seasonal items due to the ability to order more or less of a particular item, The machinery isnt continually active, allowing running costs to be reduced, Each batch can be subject to meticulous quality control and assurances, potentially causing increased employee downtime, Increased storage costs for large quantities of produced products, Errors with the batch produced will incur wasted time and cost, Periods of downtime where the specialist machinery must be altered. Have you heard of the term batch production? Rapitypes low volume manufacturing can now provide parts and assemblies with cosmetic coatings straight from the tool so no more degreasing, sanding, priming, finishing and coating is required. So, what is the most advantageous part of batch production according to you? The supplier needs to have products enough to supply to the growing demands of the customers and hence this process is used to improve the efficiency and also decrease the time needed for the whole manufacturing process to be completed. What is easily forgotten, however, is the additional time it would take to sort, stack and move the incomplete envelopes if you attempted this task the other way.