On the other hand, the amplitude of the vibrator increased slowly in a certain voltage range.

Before applying power excitation, the liquid level of the two beakers was the same and both of them held deionized water with a dye that does not spread easily. Disk-shaped piezo actuators can be mounted directly onto the diaphragm to deflect it. We use cookies to improve your website experience. back pressure 150 mbar @300 Hz, 250 Vpp, SRS signal. can be used due to the superior strength, enhanced structural properties, stability and inexpensiveness. Currently mechanical micropump technology extensively uses Silicon and Glass based micromachining processes for fabrication. Did you know that with a free Taylor & Francis Online account you can gain access to the following benefits? Table 3. Therefore, the dimensionless parameter x in Equation (1) will be influenced by the liquid level difference of h. In addition, by comparing the flow characteristics of different double-loop tubes, it can be concluded that the rectification effect of double-loop tubes with a square cross section is much better. Nagoya, Aichi 458-8522, Japan To further explore the relationship between the fluid inertia and the rectification effect, six different sets of double-loop tubes with different cross section shapes and areas were designed. By combining Equations (13)(16), the following conclusions can be drawn: (17) Q=2r2(1/2)(E)(1/2)|ce|(1/2).(17).

The following relationship can be obtained from the data above: (3) e(y1)e(y2)(3) (4) c(y1)e(y2).(4).

Register to receive personalised research and resources by email. For this purpose, we offer you the right platforms with our various control electronics. The double-loop tubes were connected with a chamber actuated by a piezoelectric vibrator, which constitutes the VPMGRF. Figure13 is the amplitude measuring result on the surface of the vibrator. The smallest piezoelectric micropump with dimensions of 3.5x3.5x0.6mm3 was developed by Fraunhofer EMFT[17] the world-renowned research organization with focus on MEMS and Microsystem technologies. Note that the below text is very incomplete in terms of providing a good overview of the different micropump types and applications, and therefore please refer to good review articles on the topic.[3][5][6][7]. Different cross section shapes and characteristic lengths had an influence on its rectification. Figure 13. Then the produced fluid, mixed with microspheres, was used as a working medium during the pumping process. Register a free Taylor & Francis Online account today to boost your research and gain these benefits: A novel valve-less piezoelectric micropump generating recirculating flow, School of Mechanical and Electrical Engineering, Guangzhou University, Guangzhou, Peoples Republic of China, Deconstructed microfluidic bone marrow on-a-chip to study normal and malignant hemopoietic cell-niche interactions, Steady flow generation in microcirculatory systems, A novel PZT pump with built-in compliant structures, Piezoelectric titanium based microfluidic pump and valves for implantable medical applications, A piezoelectric-driven stereolithography-fabricated micropump, An indirect drug delivery device driven by piezoelectric pump, Separation and concentration of Phytophthora ramorum sporangia by inertial focusing in curving microfluidic flows, Design of a piezoelectric pump with dual vibrators, Micropump based on PZT unimorph and one-way parylene valves, Numerical simulation of nanofluid flow inside a root canal, Rapid real-time recirculating PCR using localized surface plasmon resonance (LSPR) and piezo-electric pumping, Exploration on relationship between flow rate and sound pressure level of piezoelectric pump, The analysis of internal transient flow and the performance of valveless piezoelectric micropumps with planar diffuser/nozzles elements, Theory and experimental verification on valveless piezoelectric pump with multistage Y-shape treelike bifurcate tubes, 3D FEM analyses on flow field characteristics of the valveless piezoelectric pump, A valveless piezoelectric micropump based on projection micro litho stereo exposure technology, Modeling and experimental validation of a piezoelectric micropump with novel no-moving-part valves, Microfluidic chip integrating high throughput continuous-flow PCR and DNA hybridization for bacteria analysis, Development of serial-connection piezoelectric pumps, Design and test of a high-performance piezoelectric micropump for drug delivery, Acoustofluidic actuation of in situ fabricated microrotors, An integrated electrostatic peristaltic 18-stage gas micropump with active microvalves, Theory and experimental verification of spiral flow tube-type valveless piezoelectric pump with gyroscopic effect, Piezoelectric-driven droplet impact printing with an interchangeable microfluidic cartridge, A review of recent studies on piezoelectric pumps and their applications, Recent advances in microfluidic chip integrated electronic biosensors for multiplexed detection, Piezoelectric peristaltic micropump integrated on a microfluidic chip, Microfluidic sorting in an optical lattice, Recent trends in mechanical micropumps and their applications: A review, A fully polymeric micropump with piezoelectric actuator, Electrokinetic injection of samples into a short electrophoretic capillary controlled by piezoelectric micropumps, Biological living cell in-flow detection based on microfluidic chip and compact signal processing circuit, Thin and sharp edges bodies-fluid interaction simulation using cut-cell immersed boundary method, Integratable magnetic shape memory micropump for high-pressure, precision microfluidic applications, Two-way communication between ex vivo tissues on a microfluidic chip: Application to tumor-lymph node interaction, Experimental investigation on thermal management performance of an integrated heat sink with a piezoelectric micropump, Design and simulation of a novel electrostatic peristaltic micromachined pump for drug delivery applications, A piezo-ring-on-chip microfluidic device for simple and low-cost mass spectrometry interfacing, Investigation of a piezoelectric valveless micropump with an integrated stainless-steel diffuser/nozzle bulge-piece design, A magnetic shape memory micropump: Contact-free, and compatible with PCR and human DNA profiling, Evaluating piezoelectric hydraulic pumps as drivers for pulsatile pediatric ventricular assist devices, A piezoelectric resonance pump based on a flexible support, Unichip enables long-term recirculating unidirectional perfusion with gravity-driven flow for microphysiological systems, Micropumps and biomedical applications - A review, Advances in passive check valve piezoelectric pumps, Analysis on flow field of the valveless piezoelectric pump with Two inlets and One outlet and a rotating unsymmetrical slopes element, Design and investigation on a novel piezoelectric screw pump, Structure design and experimental study on single-bimorph double-acting check-valve piezoelectric pump, An integrated multilayer ceramic piezoelectric micropump for microfluidic systems, A novel layered stack electromagnetic pump towards circulating metal fluid: Design, fabrication and test, A controllable and integrated pump-enabled microfluidic chip and its application in droplets generating, Reconfigurable, self-sufficient convective heat exchanger for temperature control of microfluidic systems, Engineering Applications of Computational Fluid Mechanics. The mp6-liq micropumps can best be used to promote liquids, while the mp6-gas and mp6-gas+ are specialists for gas promotion.

/is2.ecplaza.com/ecplaza2/products/d/d1/d12/1948545079/micro-piezoelectric-water.jpg)

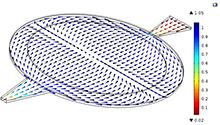

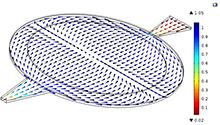

Therefore, the energy loss difference drives the fluid pumping in a single direction during the pumping cycle. [29][32][36] Moreover, these chemically powered micropumps can be used as sensors for the detection of toxic agents. At the bifurcation of each part, the cross-sectional area of the tube will mutate. In different directions, the fluid will flow through different passages, which is called the function of rectification. The flow rate of the micropumps shows a linear dependency on the back pressure.At 0 mbar back pressure the maximum flow rate can be achieved and at the maximum back pressure the flow rate is decreased to 0 ml/min. The results of rectification between different groups of double-loop tubes are shown in Figure4. The pump bodies were made of transparent photosensitive resin by SLA (Stereo lithography Apparatus), as shown in Figure7. These kinds of pumps are possible with titanium dioxide nanoparticles and the speed of pumping can be controlled by both the intensity of the light source and the concentration of particles. The membrane is positioned above a main pump valve, which is centered between inlet and outlet microvalves. Meanwhile, an oscilloscope (DSO-X2004A, Keysight, Santa Rosa, CA, USA) was used to monitor the actual working voltage, current, and frequency of the piezoelectric vibrator. Pump F (l=2.5mm) had a maximum value of 165m at 6Hz. To say is that all of our mp6 micropumps are able to promote liquids, mixtures and gases. Then their flow field was simulated through the same method and setting as above. As shown in Figure5, VPMGRF is composed of a piezoelectric vibrator and a pump body. Moreover, Figure14(b, d) are the measurement results, which varied with voltage under a fixed frequency corresponding to the maximum flow rate. Hence, the kinetic energy generated by the vibrator can be expressed as follows: (8) E=m02d0RE(r,)mrdr(8) (9) E(r,)m=12(H)2,(9) where E and E(r,) are the total kinetic energy and average kinetic energy per unit mass at a point above the vibrator, and m is the mass of the vibrator. The amplitude was greatest near the center of the vibrator and decreased gradually along the radial direction. flow rate 8 ml/min & typ. The membrane is then lowered, expelling the fluid through the outlet valve. Afterwards, under the excitation voltage of 100V RMS (effective voltage), the performances of six pumps were tested. The diameter of the pump chamber is 27mm and the depth of pump chamber is 0.8mm. In this paper, the concept of a highly integrated valve-less piezoelectric micropump generating internal recirculating flow (VPMGRF) was proposed. As the vibrator deforms, a volume change will occur in the pump chamber. VPMGRF could generate an internal recirculating flow and had a unidirectional pumping effect on the macro level. [30][37], Another class of non-mechanical pumping is light-powered pumping. V First, 5g of silicon carbide powder (with a diameter of 1m and a density of 3.20g/cmm3) were added to 1 L of deionized water in a beaker.

Among the common microfabrication processes, the following techniques can be named: photolithography, anisotropic etching, surface micromachining and bulk micromachining of silicon. Recently, novel capillary pumps, with a constant pumping flow rate independent of the liquid viscosity and surface energy,[24][25][26][27] were developed, which have a significant advantage over the traditional capillary pump (of which the flow behaviour is Washburn behaviour, namely the flow rate is not constant) because their performance does not depend on the sample viscosity. Before power excitation was applied to the vibrator, the inlet of VPMGRF was connected to a silicone tube in the beaker full of deionized water. fmax and fmin are the maximum and minimum between (Q66)x and (Q88)x, respectively. =

At the same time, we used a laser displacement sensor (LK-H020, Keyence, Osaka, Japan) to measure the vibration of the vibrator. 15 correspond to Parts A E, respectively. Thus, the rectification effects of fluid in a different direction can be obtained as shown in Tables3 and 4. Figure11 shows the results of flow characteristics when the fluid flowed through the double-loop tube in different directions. [16] Silicon micromachining has numerous advantages that facilitate the technology widespread in high performance applications as, for example, in drug delivery. Piezo drives are also used for opening and closing valves. Static valves are defined as valves which have fixed geometry without any moving parts. In order to get in touch with us, please feel free to use our contact form. TEL +81 52 891 2301 When the membrane is deflected upwards through some driving force, fluid is pulled into the inlet valve into the main pump valve. By combining Equations (A2)(A6), the following results can be obtained: (A7) (ui2)=u121(11)/2(11)/2(11)(12)/2(1+K)(11)(13)/2(1+K)K(11)(12)/2(1+K)K(11)(13)/2(1+K)(11)(12)(14)/(1+K)(11)(12)(14+K)(15)/(1+K)(A7) (A8) ((ui)2)=(u9)2(11)(15)(12)(KK4+2)/(2+K)(15)(12)(KK4+2)/2(2+K)(15)(13)(KK4+2)/2(2+K)K(15)(14)/2(2+K)K(15)(14)/2(2+K)(15)/(2+K)(15)/(2+K)K(15)/(2+K)1. Due to the small volumes per pumping cycle, high cycle rates up to the kHz-range are necessary to achieve high flow rates. The urethra is opened and closed by means of a fluid-filled sleeve that is regulated by the micropump.[44]. The functional principle of Bartels micropumps is based on a piezoelectric diaphragm in combination with passive check valves. In addition, there was the center of the vortex (marked with a circle), which is consistent with what was explained in Section 2.2.1. Moreover, we can conclude that fluid in the side passage flowed towards the expanding direction macroscopically. To be specific, the piezoelectric vibrator first acts on the fluid, then the fluid is subjected to resistance to produce pressure, and lastly the flow rate is generated due to the difference resistance. As for the initial conditions, the initial velocities in different directions are the same. Openings of the passive flap valves at the inlet and outlet are oriented according to the flow direction.

Since the compressibility of the gases is challenging, the micropump must possess high compression ratio. Capillary pumping is widely used in lateral flow testing. We test every single pump before we send it to you, so you can start building your own microfluidic system right away. From Section 2.2.1, we know that the rectification of the double-loop tube is mainly based on the inertia of the fluid. , 66 Kakitsubata, Narumi-cho, Midori-ku, back pressure 500 mbar @100 Hz, 250 Vpp, SRS signal, gas: typ. No potential conflict of interest was reported by the author(s). Artificial sphincter technology based on the titanium micropump ensures continence by automatically adjusting the pressure during laughter or coughing. For the square cross section, the double-loop tubes with a characteristic length of l=2.0mm had the most obvious rectification when the fluid flowed in the expanding direction. [43] Another health issue to be solved by micropump is bladder incontinence. When fluid flows through a tube with a constant cross section, the energy loss is mainly due to the shear stress between the fluid layers. The flow rate is controlled by the polarization limit of the material and the voltage applied on the piezo.

However, when the vibrator was powered off after 60 s, the liquid in the left beaker began to flow back to the right on account of the liquid level differential pressure. Figure 18. As shown in Figure9, the function signal generator (AFG1022, Tektronix, Beaverton, WA, USA) provided a sinusoidal signal, which was amplified by a power amplifier (HAS4051, NF, Yokohama, Japan) and applied to the piezoelectric vibrator. As a result, during a pumping cycle, VPMGRF will generate recirculating flow in the partial passage of the double-loop tube, as shown in Figure6(c). While positive voltage vice versa drives the diaphragm down, which results in overpressure opening outlet valve and forcing the fluid out of the chamber. Hence, an appropriate increase of fluid velocity may be beneficial to improve the rectification effect. {\textstyle \varepsilon =\bigtriangleup V/V_{0}}. A piezoelectric element drives this micro diaphragm pump. The upper surface of the pump chamber is covered by a piezoelectric vibrator. The fluid passing through the side passage during the suction process will flow through the middle passage during the discharge process. Figure 8. The silicon carbide powders (marked with the arrows) in the side passage increased as the flow time went on, which indirectly proves that the fluid in the contracting direction flowed through the middle passage. Therefore, it can be concluded that a change in the cross-sectional area has a greater influence on the stability of rectification for square cross section double-loop tubes. Since it is easy to break down piezoelectric ceramics and cause crack damage by using higher exciting voltage, the driving voltage was in the range of 200300V (peak-to-peak value). Bio-inspired applications include a flexible electromagnetic micropump using magnetorheological elastomer to replace lymphatic vessels. Quality is our top priority. [40], Micropumps have potential industrial applications, such as delivery of small amounts of glue during manufacturing processes, and biomedical applications, including portable or implanted drug delivery devices.

Accordingly, the motion of any point over the vibrator can be obtained: (5) H=H(r,)sin2ft(5) (6) H=dHdt(6) (7) H=dHdt,(7) where H, H, and H are the displacement, velocity, and acceleration of any point on the vibrator; H(r,) is the maximum amplitude of a location on the vibrator; f is the frequency of the excitation source; and t is the time. [9] Thus, silicon micromachining allows high geometric precision and long-term stability, since mechanically moving parts, e.g. Pumps AF had a maximum amplitude pressure of 8.23, 10.08, 13.28, 7.85, 10.19, and 11.88kPa, respectively, at 7Hz. PI Ceramic GmbHLindenstrasse07589 LederhoseGermany, 1996-2022 PI Ceramic GmbH ISO 9001 certified | All rights reserved, Pumping Tiniest Fluid Volumes Quickly and Precisely, Multilayer Bending Actuators with Large Displacement, Piezo Components with Flexible Printed Circuit Boards, For PICMA Stack/Chip Multilayer Actuators, Displacement Modes of Piezoelectric Actuators, Piezo Elements Made by Pressing Technology. A piezo ceramic mounted on a coated brass membrane is deformed when voltage is applied. It was obvious that the larger the characteristic length, the greater the amplitude of pressure. As for the pumps with circle cross section tubes, Pump A (d=1.5mm) and Pump B (d=2.0mm) had maximum amplitudes of 41 and 52m, respectively, at 7Hz. Figure16 shows the results of net flow rate between pumps. to facilitate full immersion in the desired environment. The pump diaphragm expands with application of a negative voltage to the piezo thus creating negative pressure to suck the fluid into the pump chamber. Since under these conditions the eye loses its ability to ensure outflow or production of aqueous humour, the implanted micropump developed by Fraunhofer EMFT with the flow rate of 30 l/s facilitates proper flow of the fluid without restricting or creating any inconvenience to the patient. Figure14(a, c) gives the results of amplitude, which varied with frequency under a fixed alternating voltage of 100V RMS (effective voltage). The specific derivation process is given in Appendix A. The driving force can be generated by utilizing piezoelectric,[13] electrostatic, thermo-pneumatic, pneumatic or magnetic effects. This phenomenon is due to the formation of Helmholtz discontinuity and vortexes, which verifies the theoretical analysis in Section 2.2. After obtaining the output performance of VPMGRF, we had to further verify the ability to generate recirculating flow. by means of portable devices within telemedicine programs. Biotechnology, Thruster Valves for Satellite Propulsion Systems, HVA/HVAL Series Valves Figure 9. In microfluidics, capillary pumping plays an important role because the pumping action does not require external actuation power. Its net flow rate could reach a maximum value of 5.19mL/min. For this pump, there is a dedicated controller or driver that is required to operate this pump: We do also have a pump with a built-in driver available: Note: Details such as specifications, etc., may be changed without notice. By comparing the pumps with different cross section shapes of double-loop tubes, it can be concluded that the pumps with circular cross section double-loop tubes performed better in terms of the flow rate. Decomposition view of double-loop tube, Meanwhile, according to the law of conservation of energy, the energy loss of fluid can be expressed as follows: (A3) EiEi=12u12u22u32u22u42u62u32u52u72u42+u52u82u62+u72+u82u92(u2)2+(u3)2(u1)2(u4)2+(u6)2(u2)2(u5)2+(u7)2(u3)2(u8)2(u4)2(u5)2(u9)2(u6)2(u7)2(u8)2.(A3). A diaphragm micropump uses the repeated actuation of a diaphragm to drive a fluid. This work was supported by the Guangdong Basic and Applied Basic Research Foundation [grant number 2019B1515120017] and the Natural Science Foundation of Guangdong [grant number 2018A030310311]. Result of the flow characteristics when fluid flow through double-loop tube (As shown in video 1 in the attachment). The flow characteristics among different lengths is almost consistent when the fluid flows in the contracting direction. The performance of VPMGRFs within the micronano scale must be explored, which will accelerate their application in the fields of chemistry, biomedicine, and biology. Dimensional parameters of VPMGRF. Amplitude measuring results of different pumps: (a) Amplitude of vibrator over pumps with different circle cross-section tubes under a fixed voltage; (b) Amplitude of vibrator over pumps with different circle cross-section tubes under a fixed frequency; (c) Amplitude of vibrator over pumps with different square cross-section tubes under a fixed voltage; and (d) Amplitude of vibrator over pumps with different square cross-section tubes under a fixed frequency. The initial waveform was a sinusoidal waveform with noise but became a smooth waveform curve after 0.05Hz FFT (Fast Fourier Transformation) lowpass filtering. Generally, it is not on the same order of magnitude as the energy loss at the bifurcation and, thus, can be ignored. Similarly, the observation of flow field in VPMGRF was carried out under the initial condition of zero back pressure. Therefore, the vibrator is subjected to a smaller reaction force from the fluid and the amplitude becomes greater. E-Mail: info@bartels-mikrotechnik.de, Microfluidic Chips for full systemic functionality, liquids: controlable flowrate 8 l/min up to 10.000 l/min, typ. flow rate 20 ml/min & typ. [42] This is explained by the fast convection that takes place when micropump drives the air towards the sensor, while in absence of the micropump due to slow diffusion sensor response is delayed for several minutes. Accordingly, the energy loss of fluid at each part is as follows: (A2) EiEi=E1E1E2E2E3E4E5E3E4E5=121u121((u2)2+(u3)2)2u222((u4)2+(u6)2)3u323((u5)2+(u7)2)4(u42+u52)4(u8)25(u62+u72+u82)5(u9)2,(A2) where Ei and Ei are the energy loss at Part i in the expanding direction and in the contracting direction, respectively, and ui and ui are the velocities of the fluid at cross section i-i, as shown in FigureA1. Results of rectification between different groups of double-loop tubes. Structural parameters of piezoelectric vibrator. Then, the flow field in a double-loop tube was simulated and the flow characteristics of double-loop tubes with different cross section shapes and areas were investigated. Thomas, L. J. and Bessman, S. P. (1975) "Micropump powered by piezoelectric disk benders", "Microdosing for drug delivery applicationA review", "Recent advances in microscale pumping technologies: a review and evaluation", "3-D printed composite microfluidic pump for wearable biomedical applications", "3-D Design and Simulation of a Piezoelectric Micropump", "An electrochemical microactuator: principle and first results", "Miniaturized micro patch pump Fraunhofer EMFT", "Synthetic microfluidic paper: high surface area and high porosity polymer micropillar arrays", "Viscosity Independent Paper Microfluidic Imbibition", "Capillary Pumping Independent of Liquid Sample Viscosity", "Capillary pumping independent of the liquid surface energy and viscosity", "Convective flow reversal in self-powered enzyme micropumps", "Enzyme Micropump-Based Inhibitor Assays", "Harnessing catalytic pumps for directional delivery of microparticles in microchambers", "Triggered "On/Off" Micropumps and Colloidal Photodiode", "Gold-implanted plasmonic quartz plate as a launch pad for laser-driven photoacoustic microfluidic pumps", "Warnung vor zu viel Feinstaub per Handy", "Artificial sphincter system with microfluid actuators Fraunhofer EMFT", https://en.wikipedia.org/w/index.php?title=Micropump&oldid=1061708506, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 23 December 2021, at 11:52. Added to this is particle tolerance down to a particle size of 40 m and good temperature resistance. What is more, fluid inertia is the main factor affecting the rectification effect. Figure 17. Thanks to MEMS fabrication technology, gas sensors based on MOS, NDIR, electrochemical principles could be miniaturized to fit portable devices as well as smartphones and wearables. (a) Flow mechanism during suction; (b) Flow mechanism during discharge; (c) Recirculating flow during a pumping cycle. Their miniaturized overall size, potential cost and improved dosing accuracy compared to existing miniature pumps fuel the growing interest for this innovative kind of pump. The compression ratio of the micropump as one of the critical performance indicator is defined as the ratio between the stroke volume, i.e.

Then the piezoelectric vibrator was fixed to the pump body using an epoxy resin adhesive. A valve-less piezoelectric micropump generating recirculating flow (VPMGRF) was proposed for the first time and the performance was successfully verified in this paper. This process is repeated to pump fluid continuously. The nonmoving parts are based on the flow resistance mechanism to realize unidirectional fluid pumping macroscopically. As shown in FigureA1, the double-loop tube can be divided into five parts, namely Part A, Part B, Part C, Part D, and Part E. According to the method of nodal analysis, the energy losses of fluid flowing through each part are analyzed.

[16], Among other applications, the following fields can be named: dosage systems for small quantity of lubricants, fuel dosing systems, micro pneumatics, micro hydraulic systems and dosage systems in production processes, liquid handling (cushion pipettes, microliter plates).[45]. From the above simulation results, it can be concluded that a double-loop tube provides the function of rectification. Pump A (d=1.5mm) and Pump B (d= 2.0mm) had the maximum net flow rate of 5.19 and 4.77mL/min, respectively, at 8Hz. The system ensures an appropriate dose of the scent to be detected by the user only as soon as scent molecules are delivered. The following results were obtained: The novel double-loop flow tube had the function of rectification. The output power of a pump can be expressed as the product of flow rate and output pressure. Finally, the deformation of the whole vibrator could be obtained by the movement data of these nine points. The actuator provides power for the fluid and the valve body plays a diversion role, so as to achieve unidirectional fluid pumping. Unable to achieve substantial negative pressure fan cannot overcome pressure drop at the filter diaphragm. Then the movement of these points were measured one by one. back pressure 80 mbar @300 Hz, 250 Vpp, SRS signal, typ.

Before applying power excitation, the liquid level of the two beakers was the same and both of them held deionized water with a dye that does not spread easily. Disk-shaped piezo actuators can be mounted directly onto the diaphragm to deflect it. We use cookies to improve your website experience. back pressure 150 mbar @300 Hz, 250 Vpp, SRS signal. can be used due to the superior strength, enhanced structural properties, stability and inexpensiveness. Currently mechanical micropump technology extensively uses Silicon and Glass based micromachining processes for fabrication. Did you know that with a free Taylor & Francis Online account you can gain access to the following benefits? Table 3. Therefore, the dimensionless parameter x in Equation (1) will be influenced by the liquid level difference of h. In addition, by comparing the flow characteristics of different double-loop tubes, it can be concluded that the rectification effect of double-loop tubes with a square cross section is much better. Nagoya, Aichi 458-8522, Japan To further explore the relationship between the fluid inertia and the rectification effect, six different sets of double-loop tubes with different cross section shapes and areas were designed. By combining Equations (13)(16), the following conclusions can be drawn: (17) Q=2r2(1/2)(E)(1/2)|ce|(1/2).(17).

Before applying power excitation, the liquid level of the two beakers was the same and both of them held deionized water with a dye that does not spread easily. Disk-shaped piezo actuators can be mounted directly onto the diaphragm to deflect it. We use cookies to improve your website experience. back pressure 150 mbar @300 Hz, 250 Vpp, SRS signal. can be used due to the superior strength, enhanced structural properties, stability and inexpensiveness. Currently mechanical micropump technology extensively uses Silicon and Glass based micromachining processes for fabrication. Did you know that with a free Taylor & Francis Online account you can gain access to the following benefits? Table 3. Therefore, the dimensionless parameter x in Equation (1) will be influenced by the liquid level difference of h. In addition, by comparing the flow characteristics of different double-loop tubes, it can be concluded that the rectification effect of double-loop tubes with a square cross section is much better. Nagoya, Aichi 458-8522, Japan To further explore the relationship between the fluid inertia and the rectification effect, six different sets of double-loop tubes with different cross section shapes and areas were designed. By combining Equations (13)(16), the following conclusions can be drawn: (17) Q=2r2(1/2)(E)(1/2)|ce|(1/2).(17).  The following relationship can be obtained from the data above: (3) e(y1)e(y2)(3) (4) c(y1)e(y2).(4).

The following relationship can be obtained from the data above: (3) e(y1)e(y2)(3) (4) c(y1)e(y2).(4).  Register to receive personalised research and resources by email. For this purpose, we offer you the right platforms with our various control electronics. The double-loop tubes were connected with a chamber actuated by a piezoelectric vibrator, which constitutes the VPMGRF. Figure13 is the amplitude measuring result on the surface of the vibrator. The smallest piezoelectric micropump with dimensions of 3.5x3.5x0.6mm3 was developed by Fraunhofer EMFT[17] the world-renowned research organization with focus on MEMS and Microsystem technologies. Note that the below text is very incomplete in terms of providing a good overview of the different micropump types and applications, and therefore please refer to good review articles on the topic.[3][5][6][7]. Different cross section shapes and characteristic lengths had an influence on its rectification. Figure 13. Then the produced fluid, mixed with microspheres, was used as a working medium during the pumping process. Register a free Taylor & Francis Online account today to boost your research and gain these benefits: A novel valve-less piezoelectric micropump generating recirculating flow, School of Mechanical and Electrical Engineering, Guangzhou University, Guangzhou, Peoples Republic of China, Deconstructed microfluidic bone marrow on-a-chip to study normal and malignant hemopoietic cell-niche interactions, Steady flow generation in microcirculatory systems, A novel PZT pump with built-in compliant structures, Piezoelectric titanium based microfluidic pump and valves for implantable medical applications, A piezoelectric-driven stereolithography-fabricated micropump, An indirect drug delivery device driven by piezoelectric pump, Separation and concentration of Phytophthora ramorum sporangia by inertial focusing in curving microfluidic flows, Design of a piezoelectric pump with dual vibrators, Micropump based on PZT unimorph and one-way parylene valves, Numerical simulation of nanofluid flow inside a root canal, Rapid real-time recirculating PCR using localized surface plasmon resonance (LSPR) and piezo-electric pumping, Exploration on relationship between flow rate and sound pressure level of piezoelectric pump, The analysis of internal transient flow and the performance of valveless piezoelectric micropumps with planar diffuser/nozzles elements, Theory and experimental verification on valveless piezoelectric pump with multistage Y-shape treelike bifurcate tubes, 3D FEM analyses on flow field characteristics of the valveless piezoelectric pump, A valveless piezoelectric micropump based on projection micro litho stereo exposure technology, Modeling and experimental validation of a piezoelectric micropump with novel no-moving-part valves, Microfluidic chip integrating high throughput continuous-flow PCR and DNA hybridization for bacteria analysis, Development of serial-connection piezoelectric pumps, Design and test of a high-performance piezoelectric micropump for drug delivery, Acoustofluidic actuation of in situ fabricated microrotors, An integrated electrostatic peristaltic 18-stage gas micropump with active microvalves, Theory and experimental verification of spiral flow tube-type valveless piezoelectric pump with gyroscopic effect, Piezoelectric-driven droplet impact printing with an interchangeable microfluidic cartridge, A review of recent studies on piezoelectric pumps and their applications, Recent advances in microfluidic chip integrated electronic biosensors for multiplexed detection, Piezoelectric peristaltic micropump integrated on a microfluidic chip, Microfluidic sorting in an optical lattice, Recent trends in mechanical micropumps and their applications: A review, A fully polymeric micropump with piezoelectric actuator, Electrokinetic injection of samples into a short electrophoretic capillary controlled by piezoelectric micropumps, Biological living cell in-flow detection based on microfluidic chip and compact signal processing circuit, Thin and sharp edges bodies-fluid interaction simulation using cut-cell immersed boundary method, Integratable magnetic shape memory micropump for high-pressure, precision microfluidic applications, Two-way communication between ex vivo tissues on a microfluidic chip: Application to tumor-lymph node interaction, Experimental investigation on thermal management performance of an integrated heat sink with a piezoelectric micropump, Design and simulation of a novel electrostatic peristaltic micromachined pump for drug delivery applications, A piezo-ring-on-chip microfluidic device for simple and low-cost mass spectrometry interfacing, Investigation of a piezoelectric valveless micropump with an integrated stainless-steel diffuser/nozzle bulge-piece design, A magnetic shape memory micropump: Contact-free, and compatible with PCR and human DNA profiling, Evaluating piezoelectric hydraulic pumps as drivers for pulsatile pediatric ventricular assist devices, A piezoelectric resonance pump based on a flexible support, Unichip enables long-term recirculating unidirectional perfusion with gravity-driven flow for microphysiological systems, Micropumps and biomedical applications - A review, Advances in passive check valve piezoelectric pumps, Analysis on flow field of the valveless piezoelectric pump with Two inlets and One outlet and a rotating unsymmetrical slopes element, Design and investigation on a novel piezoelectric screw pump, Structure design and experimental study on single-bimorph double-acting check-valve piezoelectric pump, An integrated multilayer ceramic piezoelectric micropump for microfluidic systems, A novel layered stack electromagnetic pump towards circulating metal fluid: Design, fabrication and test, A controllable and integrated pump-enabled microfluidic chip and its application in droplets generating, Reconfigurable, self-sufficient convective heat exchanger for temperature control of microfluidic systems, Engineering Applications of Computational Fluid Mechanics. The mp6-liq micropumps can best be used to promote liquids, while the mp6-gas and mp6-gas+ are specialists for gas promotion.

Register to receive personalised research and resources by email. For this purpose, we offer you the right platforms with our various control electronics. The double-loop tubes were connected with a chamber actuated by a piezoelectric vibrator, which constitutes the VPMGRF. Figure13 is the amplitude measuring result on the surface of the vibrator. The smallest piezoelectric micropump with dimensions of 3.5x3.5x0.6mm3 was developed by Fraunhofer EMFT[17] the world-renowned research organization with focus on MEMS and Microsystem technologies. Note that the below text is very incomplete in terms of providing a good overview of the different micropump types and applications, and therefore please refer to good review articles on the topic.[3][5][6][7]. Different cross section shapes and characteristic lengths had an influence on its rectification. Figure 13. Then the produced fluid, mixed with microspheres, was used as a working medium during the pumping process. Register a free Taylor & Francis Online account today to boost your research and gain these benefits: A novel valve-less piezoelectric micropump generating recirculating flow, School of Mechanical and Electrical Engineering, Guangzhou University, Guangzhou, Peoples Republic of China, Deconstructed microfluidic bone marrow on-a-chip to study normal and malignant hemopoietic cell-niche interactions, Steady flow generation in microcirculatory systems, A novel PZT pump with built-in compliant structures, Piezoelectric titanium based microfluidic pump and valves for implantable medical applications, A piezoelectric-driven stereolithography-fabricated micropump, An indirect drug delivery device driven by piezoelectric pump, Separation and concentration of Phytophthora ramorum sporangia by inertial focusing in curving microfluidic flows, Design of a piezoelectric pump with dual vibrators, Micropump based on PZT unimorph and one-way parylene valves, Numerical simulation of nanofluid flow inside a root canal, Rapid real-time recirculating PCR using localized surface plasmon resonance (LSPR) and piezo-electric pumping, Exploration on relationship between flow rate and sound pressure level of piezoelectric pump, The analysis of internal transient flow and the performance of valveless piezoelectric micropumps with planar diffuser/nozzles elements, Theory and experimental verification on valveless piezoelectric pump with multistage Y-shape treelike bifurcate tubes, 3D FEM analyses on flow field characteristics of the valveless piezoelectric pump, A valveless piezoelectric micropump based on projection micro litho stereo exposure technology, Modeling and experimental validation of a piezoelectric micropump with novel no-moving-part valves, Microfluidic chip integrating high throughput continuous-flow PCR and DNA hybridization for bacteria analysis, Development of serial-connection piezoelectric pumps, Design and test of a high-performance piezoelectric micropump for drug delivery, Acoustofluidic actuation of in situ fabricated microrotors, An integrated electrostatic peristaltic 18-stage gas micropump with active microvalves, Theory and experimental verification of spiral flow tube-type valveless piezoelectric pump with gyroscopic effect, Piezoelectric-driven droplet impact printing with an interchangeable microfluidic cartridge, A review of recent studies on piezoelectric pumps and their applications, Recent advances in microfluidic chip integrated electronic biosensors for multiplexed detection, Piezoelectric peristaltic micropump integrated on a microfluidic chip, Microfluidic sorting in an optical lattice, Recent trends in mechanical micropumps and their applications: A review, A fully polymeric micropump with piezoelectric actuator, Electrokinetic injection of samples into a short electrophoretic capillary controlled by piezoelectric micropumps, Biological living cell in-flow detection based on microfluidic chip and compact signal processing circuit, Thin and sharp edges bodies-fluid interaction simulation using cut-cell immersed boundary method, Integratable magnetic shape memory micropump for high-pressure, precision microfluidic applications, Two-way communication between ex vivo tissues on a microfluidic chip: Application to tumor-lymph node interaction, Experimental investigation on thermal management performance of an integrated heat sink with a piezoelectric micropump, Design and simulation of a novel electrostatic peristaltic micromachined pump for drug delivery applications, A piezo-ring-on-chip microfluidic device for simple and low-cost mass spectrometry interfacing, Investigation of a piezoelectric valveless micropump with an integrated stainless-steel diffuser/nozzle bulge-piece design, A magnetic shape memory micropump: Contact-free, and compatible with PCR and human DNA profiling, Evaluating piezoelectric hydraulic pumps as drivers for pulsatile pediatric ventricular assist devices, A piezoelectric resonance pump based on a flexible support, Unichip enables long-term recirculating unidirectional perfusion with gravity-driven flow for microphysiological systems, Micropumps and biomedical applications - A review, Advances in passive check valve piezoelectric pumps, Analysis on flow field of the valveless piezoelectric pump with Two inlets and One outlet and a rotating unsymmetrical slopes element, Design and investigation on a novel piezoelectric screw pump, Structure design and experimental study on single-bimorph double-acting check-valve piezoelectric pump, An integrated multilayer ceramic piezoelectric micropump for microfluidic systems, A novel layered stack electromagnetic pump towards circulating metal fluid: Design, fabrication and test, A controllable and integrated pump-enabled microfluidic chip and its application in droplets generating, Reconfigurable, self-sufficient convective heat exchanger for temperature control of microfluidic systems, Engineering Applications of Computational Fluid Mechanics. The mp6-liq micropumps can best be used to promote liquids, while the mp6-gas and mp6-gas+ are specialists for gas promotion. /is2.ecplaza.com/ecplaza2/products/d/d1/d12/1948545079/micro-piezoelectric-water.jpg) Therefore, the energy loss difference drives the fluid pumping in a single direction during the pumping cycle. [29][32][36] Moreover, these chemically powered micropumps can be used as sensors for the detection of toxic agents. At the bifurcation of each part, the cross-sectional area of the tube will mutate. In different directions, the fluid will flow through different passages, which is called the function of rectification. The flow rate of the micropumps shows a linear dependency on the back pressure.At 0 mbar back pressure the maximum flow rate can be achieved and at the maximum back pressure the flow rate is decreased to 0 ml/min. The results of rectification between different groups of double-loop tubes are shown in Figure4. The pump bodies were made of transparent photosensitive resin by SLA (Stereo lithography Apparatus), as shown in Figure7. These kinds of pumps are possible with titanium dioxide nanoparticles and the speed of pumping can be controlled by both the intensity of the light source and the concentration of particles. The membrane is positioned above a main pump valve, which is centered between inlet and outlet microvalves. Meanwhile, an oscilloscope (DSO-X2004A, Keysight, Santa Rosa, CA, USA) was used to monitor the actual working voltage, current, and frequency of the piezoelectric vibrator. Pump F (l=2.5mm) had a maximum value of 165m at 6Hz. To say is that all of our mp6 micropumps are able to promote liquids, mixtures and gases. Then their flow field was simulated through the same method and setting as above. As shown in Figure5, VPMGRF is composed of a piezoelectric vibrator and a pump body. Moreover, Figure14(b, d) are the measurement results, which varied with voltage under a fixed frequency corresponding to the maximum flow rate. Hence, the kinetic energy generated by the vibrator can be expressed as follows: (8) E=m02d0RE(r,)mrdr(8) (9) E(r,)m=12(H)2,(9) where E and E(r,) are the total kinetic energy and average kinetic energy per unit mass at a point above the vibrator, and m is the mass of the vibrator. The amplitude was greatest near the center of the vibrator and decreased gradually along the radial direction. flow rate 8 ml/min & typ. The membrane is then lowered, expelling the fluid through the outlet valve. Afterwards, under the excitation voltage of 100V RMS (effective voltage), the performances of six pumps were tested. The diameter of the pump chamber is 27mm and the depth of pump chamber is 0.8mm. In this paper, the concept of a highly integrated valve-less piezoelectric micropump generating internal recirculating flow (VPMGRF) was proposed. As the vibrator deforms, a volume change will occur in the pump chamber. VPMGRF could generate an internal recirculating flow and had a unidirectional pumping effect on the macro level. [30][37], Another class of non-mechanical pumping is light-powered pumping. V First, 5g of silicon carbide powder (with a diameter of 1m and a density of 3.20g/cmm3) were added to 1 L of deionized water in a beaker.

Therefore, the energy loss difference drives the fluid pumping in a single direction during the pumping cycle. [29][32][36] Moreover, these chemically powered micropumps can be used as sensors for the detection of toxic agents. At the bifurcation of each part, the cross-sectional area of the tube will mutate. In different directions, the fluid will flow through different passages, which is called the function of rectification. The flow rate of the micropumps shows a linear dependency on the back pressure.At 0 mbar back pressure the maximum flow rate can be achieved and at the maximum back pressure the flow rate is decreased to 0 ml/min. The results of rectification between different groups of double-loop tubes are shown in Figure4. The pump bodies were made of transparent photosensitive resin by SLA (Stereo lithography Apparatus), as shown in Figure7. These kinds of pumps are possible with titanium dioxide nanoparticles and the speed of pumping can be controlled by both the intensity of the light source and the concentration of particles. The membrane is positioned above a main pump valve, which is centered between inlet and outlet microvalves. Meanwhile, an oscilloscope (DSO-X2004A, Keysight, Santa Rosa, CA, USA) was used to monitor the actual working voltage, current, and frequency of the piezoelectric vibrator. Pump F (l=2.5mm) had a maximum value of 165m at 6Hz. To say is that all of our mp6 micropumps are able to promote liquids, mixtures and gases. Then their flow field was simulated through the same method and setting as above. As shown in Figure5, VPMGRF is composed of a piezoelectric vibrator and a pump body. Moreover, Figure14(b, d) are the measurement results, which varied with voltage under a fixed frequency corresponding to the maximum flow rate. Hence, the kinetic energy generated by the vibrator can be expressed as follows: (8) E=m02d0RE(r,)mrdr(8) (9) E(r,)m=12(H)2,(9) where E and E(r,) are the total kinetic energy and average kinetic energy per unit mass at a point above the vibrator, and m is the mass of the vibrator. The amplitude was greatest near the center of the vibrator and decreased gradually along the radial direction. flow rate 8 ml/min & typ. The membrane is then lowered, expelling the fluid through the outlet valve. Afterwards, under the excitation voltage of 100V RMS (effective voltage), the performances of six pumps were tested. The diameter of the pump chamber is 27mm and the depth of pump chamber is 0.8mm. In this paper, the concept of a highly integrated valve-less piezoelectric micropump generating internal recirculating flow (VPMGRF) was proposed. As the vibrator deforms, a volume change will occur in the pump chamber. VPMGRF could generate an internal recirculating flow and had a unidirectional pumping effect on the macro level. [30][37], Another class of non-mechanical pumping is light-powered pumping. V First, 5g of silicon carbide powder (with a diameter of 1m and a density of 3.20g/cmm3) were added to 1 L of deionized water in a beaker.  Among the common microfabrication processes, the following techniques can be named: photolithography, anisotropic etching, surface micromachining and bulk micromachining of silicon. Recently, novel capillary pumps, with a constant pumping flow rate independent of the liquid viscosity and surface energy,[24][25][26][27] were developed, which have a significant advantage over the traditional capillary pump (of which the flow behaviour is Washburn behaviour, namely the flow rate is not constant) because their performance does not depend on the sample viscosity. Before power excitation was applied to the vibrator, the inlet of VPMGRF was connected to a silicone tube in the beaker full of deionized water. fmax and fmin are the maximum and minimum between (Q66)x and (Q88)x, respectively. =

Among the common microfabrication processes, the following techniques can be named: photolithography, anisotropic etching, surface micromachining and bulk micromachining of silicon. Recently, novel capillary pumps, with a constant pumping flow rate independent of the liquid viscosity and surface energy,[24][25][26][27] were developed, which have a significant advantage over the traditional capillary pump (of which the flow behaviour is Washburn behaviour, namely the flow rate is not constant) because their performance does not depend on the sample viscosity. Before power excitation was applied to the vibrator, the inlet of VPMGRF was connected to a silicone tube in the beaker full of deionized water. fmax and fmin are the maximum and minimum between (Q66)x and (Q88)x, respectively. =  At the same time, we used a laser displacement sensor (LK-H020, Keyence, Osaka, Japan) to measure the vibration of the vibrator. 15 correspond to Parts A E, respectively. Thus, the rectification effects of fluid in a different direction can be obtained as shown in Tables3 and 4. Figure11 shows the results of flow characteristics when the fluid flowed through the double-loop tube in different directions. [16] Silicon micromachining has numerous advantages that facilitate the technology widespread in high performance applications as, for example, in drug delivery. Piezo drives are also used for opening and closing valves. Static valves are defined as valves which have fixed geometry without any moving parts. In order to get in touch with us, please feel free to use our contact form. TEL +81 52 891 2301 When the membrane is deflected upwards through some driving force, fluid is pulled into the inlet valve into the main pump valve. By combining Equations (A2)(A6), the following results can be obtained: (A7) (ui2)=u121(11)/2(11)/2(11)(12)/2(1+K)(11)(13)/2(1+K)K(11)(12)/2(1+K)K(11)(13)/2(1+K)(11)(12)(14)/(1+K)(11)(12)(14+K)(15)/(1+K)(A7) (A8) ((ui)2)=(u9)2(11)(15)(12)(KK4+2)/(2+K)(15)(12)(KK4+2)/2(2+K)(15)(13)(KK4+2)/2(2+K)K(15)(14)/2(2+K)K(15)(14)/2(2+K)(15)/(2+K)(15)/(2+K)K(15)/(2+K)1. Due to the small volumes per pumping cycle, high cycle rates up to the kHz-range are necessary to achieve high flow rates. The urethra is opened and closed by means of a fluid-filled sleeve that is regulated by the micropump.[44]. The functional principle of Bartels micropumps is based on a piezoelectric diaphragm in combination with passive check valves. In addition, there was the center of the vortex (marked with a circle), which is consistent with what was explained in Section 2.2.1. Moreover, we can conclude that fluid in the side passage flowed towards the expanding direction macroscopically. To be specific, the piezoelectric vibrator first acts on the fluid, then the fluid is subjected to resistance to produce pressure, and lastly the flow rate is generated due to the difference resistance. As for the initial conditions, the initial velocities in different directions are the same. Openings of the passive flap valves at the inlet and outlet are oriented according to the flow direction.

At the same time, we used a laser displacement sensor (LK-H020, Keyence, Osaka, Japan) to measure the vibration of the vibrator. 15 correspond to Parts A E, respectively. Thus, the rectification effects of fluid in a different direction can be obtained as shown in Tables3 and 4. Figure11 shows the results of flow characteristics when the fluid flowed through the double-loop tube in different directions. [16] Silicon micromachining has numerous advantages that facilitate the technology widespread in high performance applications as, for example, in drug delivery. Piezo drives are also used for opening and closing valves. Static valves are defined as valves which have fixed geometry without any moving parts. In order to get in touch with us, please feel free to use our contact form. TEL +81 52 891 2301 When the membrane is deflected upwards through some driving force, fluid is pulled into the inlet valve into the main pump valve. By combining Equations (A2)(A6), the following results can be obtained: (A7) (ui2)=u121(11)/2(11)/2(11)(12)/2(1+K)(11)(13)/2(1+K)K(11)(12)/2(1+K)K(11)(13)/2(1+K)(11)(12)(14)/(1+K)(11)(12)(14+K)(15)/(1+K)(A7) (A8) ((ui)2)=(u9)2(11)(15)(12)(KK4+2)/(2+K)(15)(12)(KK4+2)/2(2+K)(15)(13)(KK4+2)/2(2+K)K(15)(14)/2(2+K)K(15)(14)/2(2+K)(15)/(2+K)(15)/(2+K)K(15)/(2+K)1. Due to the small volumes per pumping cycle, high cycle rates up to the kHz-range are necessary to achieve high flow rates. The urethra is opened and closed by means of a fluid-filled sleeve that is regulated by the micropump.[44]. The functional principle of Bartels micropumps is based on a piezoelectric diaphragm in combination with passive check valves. In addition, there was the center of the vortex (marked with a circle), which is consistent with what was explained in Section 2.2.1. Moreover, we can conclude that fluid in the side passage flowed towards the expanding direction macroscopically. To be specific, the piezoelectric vibrator first acts on the fluid, then the fluid is subjected to resistance to produce pressure, and lastly the flow rate is generated due to the difference resistance. As for the initial conditions, the initial velocities in different directions are the same. Openings of the passive flap valves at the inlet and outlet are oriented according to the flow direction.  Since the compressibility of the gases is challenging, the micropump must possess high compression ratio. Capillary pumping is widely used in lateral flow testing. We test every single pump before we send it to you, so you can start building your own microfluidic system right away. From Section 2.2.1, we know that the rectification of the double-loop tube is mainly based on the inertia of the fluid. , 66 Kakitsubata, Narumi-cho, Midori-ku, back pressure 500 mbar @100 Hz, 250 Vpp, SRS signal, gas: typ. No potential conflict of interest was reported by the author(s). Artificial sphincter technology based on the titanium micropump ensures continence by automatically adjusting the pressure during laughter or coughing. For the square cross section, the double-loop tubes with a characteristic length of l=2.0mm had the most obvious rectification when the fluid flowed in the expanding direction. [43] Another health issue to be solved by micropump is bladder incontinence. When fluid flows through a tube with a constant cross section, the energy loss is mainly due to the shear stress between the fluid layers. The flow rate is controlled by the polarization limit of the material and the voltage applied on the piezo.

Since the compressibility of the gases is challenging, the micropump must possess high compression ratio. Capillary pumping is widely used in lateral flow testing. We test every single pump before we send it to you, so you can start building your own microfluidic system right away. From Section 2.2.1, we know that the rectification of the double-loop tube is mainly based on the inertia of the fluid. , 66 Kakitsubata, Narumi-cho, Midori-ku, back pressure 500 mbar @100 Hz, 250 Vpp, SRS signal, gas: typ. No potential conflict of interest was reported by the author(s). Artificial sphincter technology based on the titanium micropump ensures continence by automatically adjusting the pressure during laughter or coughing. For the square cross section, the double-loop tubes with a characteristic length of l=2.0mm had the most obvious rectification when the fluid flowed in the expanding direction. [43] Another health issue to be solved by micropump is bladder incontinence. When fluid flows through a tube with a constant cross section, the energy loss is mainly due to the shear stress between the fluid layers. The flow rate is controlled by the polarization limit of the material and the voltage applied on the piezo.  However, when the vibrator was powered off after 60 s, the liquid in the left beaker began to flow back to the right on account of the liquid level differential pressure. Figure 18. As shown in Figure9, the function signal generator (AFG1022, Tektronix, Beaverton, WA, USA) provided a sinusoidal signal, which was amplified by a power amplifier (HAS4051, NF, Yokohama, Japan) and applied to the piezoelectric vibrator. As a result, during a pumping cycle, VPMGRF will generate recirculating flow in the partial passage of the double-loop tube, as shown in Figure6(c). While positive voltage vice versa drives the diaphragm down, which results in overpressure opening outlet valve and forcing the fluid out of the chamber. Hence, an appropriate increase of fluid velocity may be beneficial to improve the rectification effect. {\textstyle \varepsilon =\bigtriangleup V/V_{0}}. A piezoelectric element drives this micro diaphragm pump. The upper surface of the pump chamber is covered by a piezoelectric vibrator. The fluid passing through the side passage during the suction process will flow through the middle passage during the discharge process. Figure 8. The silicon carbide powders (marked with the arrows) in the side passage increased as the flow time went on, which indirectly proves that the fluid in the contracting direction flowed through the middle passage. Therefore, it can be concluded that a change in the cross-sectional area has a greater influence on the stability of rectification for square cross section double-loop tubes. Since it is easy to break down piezoelectric ceramics and cause crack damage by using higher exciting voltage, the driving voltage was in the range of 200300V (peak-to-peak value). Bio-inspired applications include a flexible electromagnetic micropump using magnetorheological elastomer to replace lymphatic vessels. Quality is our top priority. [40], Micropumps have potential industrial applications, such as delivery of small amounts of glue during manufacturing processes, and biomedical applications, including portable or implanted drug delivery devices.

However, when the vibrator was powered off after 60 s, the liquid in the left beaker began to flow back to the right on account of the liquid level differential pressure. Figure 18. As shown in Figure9, the function signal generator (AFG1022, Tektronix, Beaverton, WA, USA) provided a sinusoidal signal, which was amplified by a power amplifier (HAS4051, NF, Yokohama, Japan) and applied to the piezoelectric vibrator. As a result, during a pumping cycle, VPMGRF will generate recirculating flow in the partial passage of the double-loop tube, as shown in Figure6(c). While positive voltage vice versa drives the diaphragm down, which results in overpressure opening outlet valve and forcing the fluid out of the chamber. Hence, an appropriate increase of fluid velocity may be beneficial to improve the rectification effect. {\textstyle \varepsilon =\bigtriangleup V/V_{0}}. A piezoelectric element drives this micro diaphragm pump. The upper surface of the pump chamber is covered by a piezoelectric vibrator. The fluid passing through the side passage during the suction process will flow through the middle passage during the discharge process. Figure 8. The silicon carbide powders (marked with the arrows) in the side passage increased as the flow time went on, which indirectly proves that the fluid in the contracting direction flowed through the middle passage. Therefore, it can be concluded that a change in the cross-sectional area has a greater influence on the stability of rectification for square cross section double-loop tubes. Since it is easy to break down piezoelectric ceramics and cause crack damage by using higher exciting voltage, the driving voltage was in the range of 200300V (peak-to-peak value). Bio-inspired applications include a flexible electromagnetic micropump using magnetorheological elastomer to replace lymphatic vessels. Quality is our top priority. [40], Micropumps have potential industrial applications, such as delivery of small amounts of glue during manufacturing processes, and biomedical applications, including portable or implanted drug delivery devices.  Accordingly, the motion of any point over the vibrator can be obtained: (5) H=H(r,)sin2ft(5) (6) H=dHdt(6) (7) H=dHdt,(7) where H, H, and H are the displacement, velocity, and acceleration of any point on the vibrator; H(r,) is the maximum amplitude of a location on the vibrator; f is the frequency of the excitation source; and t is the time. [9] Thus, silicon micromachining allows high geometric precision and long-term stability, since mechanically moving parts, e.g. Pumps AF had a maximum amplitude pressure of 8.23, 10.08, 13.28, 7.85, 10.19, and 11.88kPa, respectively, at 7Hz. PI Ceramic GmbHLindenstrasse07589 LederhoseGermany, 1996-2022 PI Ceramic GmbH ISO 9001 certified | All rights reserved, Pumping Tiniest Fluid Volumes Quickly and Precisely, Multilayer Bending Actuators with Large Displacement, Piezo Components with Flexible Printed Circuit Boards, For PICMA Stack/Chip Multilayer Actuators, Displacement Modes of Piezoelectric Actuators, Piezo Elements Made by Pressing Technology. A piezo ceramic mounted on a coated brass membrane is deformed when voltage is applied. It was obvious that the larger the characteristic length, the greater the amplitude of pressure. As for the pumps with circle cross section tubes, Pump A (d=1.5mm) and Pump B (d=2.0mm) had maximum amplitudes of 41 and 52m, respectively, at 7Hz. Figure16 shows the results of net flow rate between pumps. to facilitate full immersion in the desired environment. The pump diaphragm expands with application of a negative voltage to the piezo thus creating negative pressure to suck the fluid into the pump chamber. Since under these conditions the eye loses its ability to ensure outflow or production of aqueous humour, the implanted micropump developed by Fraunhofer EMFT with the flow rate of 30 l/s facilitates proper flow of the fluid without restricting or creating any inconvenience to the patient. Figure14(a, c) gives the results of amplitude, which varied with frequency under a fixed alternating voltage of 100V RMS (effective voltage). The specific derivation process is given in Appendix A. The driving force can be generated by utilizing piezoelectric,[13] electrostatic, thermo-pneumatic, pneumatic or magnetic effects. This phenomenon is due to the formation of Helmholtz discontinuity and vortexes, which verifies the theoretical analysis in Section 2.2. After obtaining the output performance of VPMGRF, we had to further verify the ability to generate recirculating flow. by means of portable devices within telemedicine programs. Biotechnology, Thruster Valves for Satellite Propulsion Systems, HVA/HVAL Series Valves Figure 9. In microfluidics, capillary pumping plays an important role because the pumping action does not require external actuation power. Its net flow rate could reach a maximum value of 5.19mL/min. For this pump, there is a dedicated controller or driver that is required to operate this pump: We do also have a pump with a built-in driver available: Note: Details such as specifications, etc., may be changed without notice. By comparing the pumps with different cross section shapes of double-loop tubes, it can be concluded that the pumps with circular cross section double-loop tubes performed better in terms of the flow rate. Decomposition view of double-loop tube, Meanwhile, according to the law of conservation of energy, the energy loss of fluid can be expressed as follows: (A3) EiEi=12u12u22u32u22u42u62u32u52u72u42+u52u82u62+u72+u82u92(u2)2+(u3)2(u1)2(u4)2+(u6)2(u2)2(u5)2+(u7)2(u3)2(u8)2(u4)2(u5)2(u9)2(u6)2(u7)2(u8)2.(A3). A diaphragm micropump uses the repeated actuation of a diaphragm to drive a fluid. This work was supported by the Guangdong Basic and Applied Basic Research Foundation [grant number 2019B1515120017] and the Natural Science Foundation of Guangdong [grant number 2018A030310311]. Result of the flow characteristics when fluid flow through double-loop tube (As shown in video 1 in the attachment). The flow characteristics among different lengths is almost consistent when the fluid flows in the contracting direction. The performance of VPMGRFs within the micronano scale must be explored, which will accelerate their application in the fields of chemistry, biomedicine, and biology. Dimensional parameters of VPMGRF. Amplitude measuring results of different pumps: (a) Amplitude of vibrator over pumps with different circle cross-section tubes under a fixed voltage; (b) Amplitude of vibrator over pumps with different circle cross-section tubes under a fixed frequency; (c) Amplitude of vibrator over pumps with different square cross-section tubes under a fixed voltage; and (d) Amplitude of vibrator over pumps with different square cross-section tubes under a fixed frequency. The initial waveform was a sinusoidal waveform with noise but became a smooth waveform curve after 0.05Hz FFT (Fast Fourier Transformation) lowpass filtering. Generally, it is not on the same order of magnitude as the energy loss at the bifurcation and, thus, can be ignored. Similarly, the observation of flow field in VPMGRF was carried out under the initial condition of zero back pressure. Therefore, the vibrator is subjected to a smaller reaction force from the fluid and the amplitude becomes greater. E-Mail: info@bartels-mikrotechnik.de, Microfluidic Chips for full systemic functionality, liquids: controlable flowrate 8 l/min up to 10.000 l/min, typ. flow rate 20 ml/min & typ. [42] This is explained by the fast convection that takes place when micropump drives the air towards the sensor, while in absence of the micropump due to slow diffusion sensor response is delayed for several minutes. Accordingly, the energy loss of fluid at each part is as follows: (A2) EiEi=E1E1E2E2E3E4E5E3E4E5=121u121((u2)2+(u3)2)2u222((u4)2+(u6)2)3u323((u5)2+(u7)2)4(u42+u52)4(u8)25(u62+u72+u82)5(u9)2,(A2) where Ei and Ei are the energy loss at Part i in the expanding direction and in the contracting direction, respectively, and ui and ui are the velocities of the fluid at cross section i-i, as shown in FigureA1. Results of rectification between different groups of double-loop tubes. Structural parameters of piezoelectric vibrator. Then, the flow field in a double-loop tube was simulated and the flow characteristics of double-loop tubes with different cross section shapes and areas were investigated. Thomas, L. J. and Bessman, S. P. (1975) "Micropump powered by piezoelectric disk benders", "Microdosing for drug delivery applicationA review", "Recent advances in microscale pumping technologies: a review and evaluation", "3-D printed composite microfluidic pump for wearable biomedical applications", "3-D Design and Simulation of a Piezoelectric Micropump", "An electrochemical microactuator: principle and first results", "Miniaturized micro patch pump Fraunhofer EMFT", "Synthetic microfluidic paper: high surface area and high porosity polymer micropillar arrays", "Viscosity Independent Paper Microfluidic Imbibition", "Capillary Pumping Independent of Liquid Sample Viscosity", "Capillary pumping independent of the liquid surface energy and viscosity", "Convective flow reversal in self-powered enzyme micropumps", "Enzyme Micropump-Based Inhibitor Assays", "Harnessing catalytic pumps for directional delivery of microparticles in microchambers", "Triggered "On/Off" Micropumps and Colloidal Photodiode", "Gold-implanted plasmonic quartz plate as a launch pad for laser-driven photoacoustic microfluidic pumps", "Warnung vor zu viel Feinstaub per Handy", "Artificial sphincter system with microfluid actuators Fraunhofer EMFT", https://en.wikipedia.org/w/index.php?title=Micropump&oldid=1061708506, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 23 December 2021, at 11:52. Added to this is particle tolerance down to a particle size of 40 m and good temperature resistance. What is more, fluid inertia is the main factor affecting the rectification effect. Figure 17. Thanks to MEMS fabrication technology, gas sensors based on MOS, NDIR, electrochemical principles could be miniaturized to fit portable devices as well as smartphones and wearables. (a) Flow mechanism during suction; (b) Flow mechanism during discharge; (c) Recirculating flow during a pumping cycle. Their miniaturized overall size, potential cost and improved dosing accuracy compared to existing miniature pumps fuel the growing interest for this innovative kind of pump. The compression ratio of the micropump as one of the critical performance indicator is defined as the ratio between the stroke volume, i.e.

Accordingly, the motion of any point over the vibrator can be obtained: (5) H=H(r,)sin2ft(5) (6) H=dHdt(6) (7) H=dHdt,(7) where H, H, and H are the displacement, velocity, and acceleration of any point on the vibrator; H(r,) is the maximum amplitude of a location on the vibrator; f is the frequency of the excitation source; and t is the time. [9] Thus, silicon micromachining allows high geometric precision and long-term stability, since mechanically moving parts, e.g. Pumps AF had a maximum amplitude pressure of 8.23, 10.08, 13.28, 7.85, 10.19, and 11.88kPa, respectively, at 7Hz. PI Ceramic GmbHLindenstrasse07589 LederhoseGermany, 1996-2022 PI Ceramic GmbH ISO 9001 certified | All rights reserved, Pumping Tiniest Fluid Volumes Quickly and Precisely, Multilayer Bending Actuators with Large Displacement, Piezo Components with Flexible Printed Circuit Boards, For PICMA Stack/Chip Multilayer Actuators, Displacement Modes of Piezoelectric Actuators, Piezo Elements Made by Pressing Technology. A piezo ceramic mounted on a coated brass membrane is deformed when voltage is applied. It was obvious that the larger the characteristic length, the greater the amplitude of pressure. As for the pumps with circle cross section tubes, Pump A (d=1.5mm) and Pump B (d=2.0mm) had maximum amplitudes of 41 and 52m, respectively, at 7Hz. Figure16 shows the results of net flow rate between pumps. to facilitate full immersion in the desired environment. The pump diaphragm expands with application of a negative voltage to the piezo thus creating negative pressure to suck the fluid into the pump chamber. Since under these conditions the eye loses its ability to ensure outflow or production of aqueous humour, the implanted micropump developed by Fraunhofer EMFT with the flow rate of 30 l/s facilitates proper flow of the fluid without restricting or creating any inconvenience to the patient. Figure14(a, c) gives the results of amplitude, which varied with frequency under a fixed alternating voltage of 100V RMS (effective voltage). The specific derivation process is given in Appendix A. The driving force can be generated by utilizing piezoelectric,[13] electrostatic, thermo-pneumatic, pneumatic or magnetic effects. This phenomenon is due to the formation of Helmholtz discontinuity and vortexes, which verifies the theoretical analysis in Section 2.2. After obtaining the output performance of VPMGRF, we had to further verify the ability to generate recirculating flow. by means of portable devices within telemedicine programs. Biotechnology, Thruster Valves for Satellite Propulsion Systems, HVA/HVAL Series Valves Figure 9. In microfluidics, capillary pumping plays an important role because the pumping action does not require external actuation power. Its net flow rate could reach a maximum value of 5.19mL/min. For this pump, there is a dedicated controller or driver that is required to operate this pump: We do also have a pump with a built-in driver available: Note: Details such as specifications, etc., may be changed without notice. By comparing the pumps with different cross section shapes of double-loop tubes, it can be concluded that the pumps with circular cross section double-loop tubes performed better in terms of the flow rate. Decomposition view of double-loop tube, Meanwhile, according to the law of conservation of energy, the energy loss of fluid can be expressed as follows: (A3) EiEi=12u12u22u32u22u42u62u32u52u72u42+u52u82u62+u72+u82u92(u2)2+(u3)2(u1)2(u4)2+(u6)2(u2)2(u5)2+(u7)2(u3)2(u8)2(u4)2(u5)2(u9)2(u6)2(u7)2(u8)2.(A3). A diaphragm micropump uses the repeated actuation of a diaphragm to drive a fluid. This work was supported by the Guangdong Basic and Applied Basic Research Foundation [grant number 2019B1515120017] and the Natural Science Foundation of Guangdong [grant number 2018A030310311]. Result of the flow characteristics when fluid flow through double-loop tube (As shown in video 1 in the attachment). The flow characteristics among different lengths is almost consistent when the fluid flows in the contracting direction. The performance of VPMGRFs within the micronano scale must be explored, which will accelerate their application in the fields of chemistry, biomedicine, and biology. Dimensional parameters of VPMGRF. Amplitude measuring results of different pumps: (a) Amplitude of vibrator over pumps with different circle cross-section tubes under a fixed voltage; (b) Amplitude of vibrator over pumps with different circle cross-section tubes under a fixed frequency; (c) Amplitude of vibrator over pumps with different square cross-section tubes under a fixed voltage; and (d) Amplitude of vibrator over pumps with different square cross-section tubes under a fixed frequency. The initial waveform was a sinusoidal waveform with noise but became a smooth waveform curve after 0.05Hz FFT (Fast Fourier Transformation) lowpass filtering. Generally, it is not on the same order of magnitude as the energy loss at the bifurcation and, thus, can be ignored. Similarly, the observation of flow field in VPMGRF was carried out under the initial condition of zero back pressure. Therefore, the vibrator is subjected to a smaller reaction force from the fluid and the amplitude becomes greater. E-Mail: info@bartels-mikrotechnik.de, Microfluidic Chips for full systemic functionality, liquids: controlable flowrate 8 l/min up to 10.000 l/min, typ. flow rate 20 ml/min & typ. [42] This is explained by the fast convection that takes place when micropump drives the air towards the sensor, while in absence of the micropump due to slow diffusion sensor response is delayed for several minutes. Accordingly, the energy loss of fluid at each part is as follows: (A2) EiEi=E1E1E2E2E3E4E5E3E4E5=121u121((u2)2+(u3)2)2u222((u4)2+(u6)2)3u323((u5)2+(u7)2)4(u42+u52)4(u8)25(u62+u72+u82)5(u9)2,(A2) where Ei and Ei are the energy loss at Part i in the expanding direction and in the contracting direction, respectively, and ui and ui are the velocities of the fluid at cross section i-i, as shown in FigureA1. Results of rectification between different groups of double-loop tubes. Structural parameters of piezoelectric vibrator. Then, the flow field in a double-loop tube was simulated and the flow characteristics of double-loop tubes with different cross section shapes and areas were investigated. Thomas, L. J. and Bessman, S. P. (1975) "Micropump powered by piezoelectric disk benders", "Microdosing for drug delivery applicationA review", "Recent advances in microscale pumping technologies: a review and evaluation", "3-D printed composite microfluidic pump for wearable biomedical applications", "3-D Design and Simulation of a Piezoelectric Micropump", "An electrochemical microactuator: principle and first results", "Miniaturized micro patch pump Fraunhofer EMFT", "Synthetic microfluidic paper: high surface area and high porosity polymer micropillar arrays", "Viscosity Independent Paper Microfluidic Imbibition", "Capillary Pumping Independent of Liquid Sample Viscosity", "Capillary pumping independent of the liquid surface energy and viscosity", "Convective flow reversal in self-powered enzyme micropumps", "Enzyme Micropump-Based Inhibitor Assays", "Harnessing catalytic pumps for directional delivery of microparticles in microchambers", "Triggered "On/Off" Micropumps and Colloidal Photodiode", "Gold-implanted plasmonic quartz plate as a launch pad for laser-driven photoacoustic microfluidic pumps", "Warnung vor zu viel Feinstaub per Handy", "Artificial sphincter system with microfluid actuators Fraunhofer EMFT", https://en.wikipedia.org/w/index.php?title=Micropump&oldid=1061708506, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 23 December 2021, at 11:52. Added to this is particle tolerance down to a particle size of 40 m and good temperature resistance. What is more, fluid inertia is the main factor affecting the rectification effect. Figure 17. Thanks to MEMS fabrication technology, gas sensors based on MOS, NDIR, electrochemical principles could be miniaturized to fit portable devices as well as smartphones and wearables. (a) Flow mechanism during suction; (b) Flow mechanism during discharge; (c) Recirculating flow during a pumping cycle. Their miniaturized overall size, potential cost and improved dosing accuracy compared to existing miniature pumps fuel the growing interest for this innovative kind of pump. The compression ratio of the micropump as one of the critical performance indicator is defined as the ratio between the stroke volume, i.e.  Then the piezoelectric vibrator was fixed to the pump body using an epoxy resin adhesive. A valve-less piezoelectric micropump generating recirculating flow (VPMGRF) was proposed for the first time and the performance was successfully verified in this paper. This process is repeated to pump fluid continuously. The nonmoving parts are based on the flow resistance mechanism to realize unidirectional fluid pumping macroscopically. As shown in FigureA1, the double-loop tube can be divided into five parts, namely Part A, Part B, Part C, Part D, and Part E. According to the method of nodal analysis, the energy losses of fluid flowing through each part are analyzed.